Endangered Fermented Foods

Through selective breeding and domestication of plants and livestock, the world’s food system has lost diversity to an alarming degree. Crops are monocultures and animals are single species. Journalist and author Dan Saladino argues it’s vital to the health of humanity and our planet to save these traditional foods.

“There’s an incredible amount of homogenization taking place in the last century, which has resulted in a huge amount of concentration of power in the food system but also a decline in the amount of biodiversity,” says Saladino, author of Eating to Extinction. “That agricultural and biological diversity is disappearing and it’s taken us thousands, millions of years for plant, animal evolution to get to this point.”

Saladino was a keynote speaker at The Fermentation Association’s conference FERMENTATION 2022, his first in-person talk in the United States since his book was released in February. A journalist with the BBC, Saladino was also an active participant in the event, attending multiple days’ worth of educational sessions. He called the conference “mind expanding.”

“I thought I knew about fermentation, when in fact I know very little,” Saladino said to the crowd in his keynote. “We’ve been bemused by the media reports that fermentation is a fad or fashion. What we know is that the modern food system in the last 150 years is the fad. It’s barely a blip in the context of our evolution as species, and it’s the way we’ve survived as a species over thousands of years.”

Eating to Extinction includes 40 stories of endangered foods and beverages, just touching on a fraction of what is happening around the world. To date, over 5,000 endangered items from 130 different countries have been cataloged by the Slow Food Foundation’s project the Ark of Taste.

During FERMENTATION 2022, Saladino centered his remarks around the endangered fermented foods he chronicled in his book – Salers cheese, skerpikjøt, oca, O-Higu soybeans, lambic beer, pu’erh tea, qvevri wine, perry and wild forest coffee. Here are some of the highlights of his presentation.

Salers cheese (Augergne, Central France)

Fermentation was a survival strategy for many early humans, a fact especially evident in the origins of cheesemaking. In areas like Salers in central France, villagers live in inhospitable mountain areas where it’s difficult to access food. In the spring each year, cheesemakers travel up the mountains with their cattle and live like nomads for months.

“It’s extremely laborious, hard work,” Saladino says, noting there’s only a handful of Salers cheese producers left in France. He marvels at “the ingenuity of taking animals up and out to pasture in places where the energy from the sun and from the soil is creating pastures with grasses with wildflowers and herbs and so on.”

Unlike with modern cheese, no starter cultures are used to make Salers cheese. The microbial activity is provided by the environment – the pasture, the animals and even the leftover lactic acid bacteria in the milk barrels. Because of diversity, the taste is rarely consistent, ranging season to season from mild to aggressive.

“The idea of cheesemaking is a way humans expand and explore these new territories assisted by the crucial characters in this: the microbes,” he adds. “It can be argued that cheese is one of most beautiful ways to capture the landscape of food – the microbial activity in grasses, the interaction of breeds of animals that are adapted to the landscape. It’s creating something unique to that place.”

Skerpikjøt (Faroe Islands)

Skerpikjøt “is a powerful illustration to our relationship with animals, with meat eating,” Saladino says. It is fermented mutton and unique to Denmark’s Faroe Islands. Today’s farmers selectively breed their sheep for ideal wool production, then slaughter the lambs for meat. In the Faroes, “the idea of eating lamb was a relatively new concept.” Sheep are considered vital to the farm as long as they’re still producing wool and milk.

Once a sheep dies or is killed, the mutton carcass is air-dried and fermented in a shed for 9-18 months. The resulting product is “said to be anything between Parmesan and death. It certainly has got a challenging, funky fragrance,” Saldino says.

But it contrasts traditional and modern food practices. Skerpikjøt is meant to be consumed in small quantities, delicate slivers of animal proteins used as a garnish. Contemporary meat is served in large portions and meant to be consumed quickly.

Oca (Andes, Bolivia),

In the Andes – “one of the highest, coldest and toughest places on Earth to live” – humans have relied on wild plants like oca, a tuber. After oca is harvested, it’s taken to the Pelechuco River. Holes are dug on the riverbank, then filled with water, hay and muna (Andean mint). Sacks of oca are placed in the holes, weighted down by stones, and left to ferment for a month. This process is vital as it leaches out acid.

“Through processing, this becomes an amazing food,” Saladino says.

But cities are demanding certain types of potatoes, encouraging remote villagers to plant monocultures of potatoes which are prone to diseases. The farmers end up in debt, buying fertilizers and pesticides to grow potatoes.

“For thousands of years, oca and this fermentation technique and the process to make these hockey pucks of carbohydrates and energy kept them alive in that area,” Saladino says. “It’s a diversity that is fast disappearing from the Andes.”

O-Higu soybeans (Okinawa, Japan)

The modern food industry is threatening the O-Higu soybean, too. It was an ideal soybean species – fast-growing, so it can be harvested before the rainy season and the arrival of insects.

“But by the 20th century, the soy culture pretty much disappeared,” Saladino says.

With World War II came one of America’s biggest military bases to Japan. U.S. leaders dictated what food could be planted on the island. Okinawa was self-sufficient in local soy until American soy was introduced.

Lambic Beer (Belgium)

Saldino explained that, after a spring/summer harvest, Belgian farmers became brewers. They used their leftover wheat to create brews unique to the region.

But by the 1950s and 1960s, larger brewers began buying up the smaller ones. Anheuser-Busch InBev now produces one in four beers drunk around the world.

“There [is] story after story of these distinctive, unique, small breweries disappearing as they are bought up or absorbed into this growing, expanding empire of brewing,” Saladino says. “It’s probably one of the most striking cases of corporate consolidation of a drink and food product.”

Saladino stressed not all is lost. He shared stories of scientists, researchers and local people trying to save endangered foods, collecting seeds, restoring crops and combining traditional and modern-day practices to preserve the world’s rare foods.

“There have been so many fascinating stories of science and research discussed over the last few days at this conference, and I think the existence of The Fermentation Association is exciting because it is bringing together tradition, culture, science, culinary skills, all of these things we know food is,” Saladino added. “Food is economics, politics, geography, anthropology, nutrition. What I’m arguing is that these clues or glimpses into the past for these endangered foods, they’re not just some kind of a food museum or an online catalog. They are the solutions that can help us resolve some of the biggest food challenges we have.”

- Published in Food & Flavor

The Rise of Fermented Foods and -Biotics

Microbes on our bodies outnumber our human cells. Can we improve our health using microbes?

“(Humans) are minuscule compared to the genetic content of our microbiomes,” says Maria Marco, PhD, professor of food science at the University of California, Davis (and a TFA Advisory Board Member). “We now have a much better handle that microbes are good for us.”

Marco was a featured speaker at an Institute for the Advancement of Food and Nutrition Sciences (IAFNS) webinar, “What’s What?! Probiotics, Postbiotics, Prebiotics, Synbiotics and Fermented Foods.” Also speaking was Karen Scott, PhD, professor at University of Aberdeen, Scotland, and co-director of the university’s Centre for Bacteria in Health and Disease.

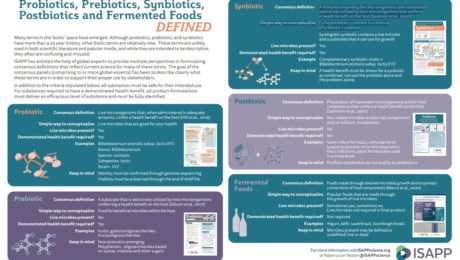

While probiotic-containing foods and supplements have been around for decades – or, in the case of fermented foods, tens of thousands of years – they have become more common recently . But “as the terms relevant to this space proliferate, so does confusion,” states IAFNS.

Using definitions created by the International Scientific Association for Postbiotics and Prebiotics (ISAPP), Marco and Scott presented the attributes of fermented foods, probiotics, prebiotics, synbiotics and postbiotics.

The majority of microbes in the human body are in the digestive tract, Marco notes: “We have frankly very few ways we can direct them towards what we need for sustaining our health and well being.” Humans can’t control age or genetics and have little impact over environmental factors.

What we can control, though, are the kinds of foods, beverages and supplements we consume.

Fermented Foods

It’s estimated that one third of the human diet globally is made up of fermented foods. But this is a diverse category that shares one common element: “Fermented foods are made by microbes,” Marco adds. “You can’t have a fermented food without a microbe.”

This distinction separates true fermented foods from those that look fermented but don’t have microbes involved. Quick pickles or cucumbers soaked in a vinegar brine, for example, are not fermented. And there are fermented foods that originally contained live microbes, but where those microbes are killed during production — in sourdough bread, shelf-stable pickles and veggies, sausage, soy sauce, vinegar, wine, most beers, coffee and chocolate. Fermented foods that contain live, viable microbes include yogurt, kefir, most cheeses, natto, tempeh, kimchi, dry fermented sausages, most kombuchas and some beers.

“There’s confusion among scientists and the public about what is a fermented food,” Marco says.

Fermented foods provide health benefits by transforming food ingredients, synthesizing nutrients and providing live microbes.There is some evidence they aid digestive health (kefir, sourdough), improve mood and behavior (wine, beer, coffee), reduce inflammatory bowel syndrome (sauerkraut, sourdough), aid weight loss and fight obesity (yogurt, kimchi), and enhance immunity (kimchi, yogurt), bone health (yogurt, kefir, natto) and the cardiovascular system (yogurt, cheese, coffee, wine, beer, vinegar). But there are only a few studies on humans that have examined these topics. More studies of fermented foods are needed to document and prove these benefits.

Probiotics

Probiotics, on the other hand, have clinical evidence documenting their health benefits. “We know probiotics improve human health,” Marco says.

The concept of probiotics dates back to the early 20th century, but the word “probiotic” has now become a household term. Most scientific studies involving probiotics look at their benefit to the digestive tract, but new research is examining their impact on the respiratory system and in aiding vaginal health.

Probiotics are different from fermented foods because they are defined at the strain level and their genomic sequence is known, Marco adds. Probiotics should be alive at the time of consumption in order to provide a health benefit.

Postbiotics

Postbiotics are dead microorganisms. It is a relatively new term — also referred to as parabiotics, non-viable probiotics, heat-killed probiotics and tyndallized probiotics — and there’s emerging research around the health benefits of consuming these inanimate cells.

“I think we’ll be seeing a lot more attention to this concept as we begin to understand how probiotics work and gut microbiomes work and the specific compounds needed to modulate our health,” according to Marco.

Prebiotics

Prebiotics are, according to ISAPP, “A substrate selectively utilized by host microorganisms conferring a health benefit on the host.”

“It basically means a food source for microorganisms that live in or on a source,” Scott says. “But any candidate for a prebiotic must confer a health benefit.”

Prebiotics are not processed in the small intestine. They reach the large intestine undigested, where they serve as nutrients for beneficial microorganisms in our gut microbiome.

Synbiotics

Synbiotics are mixtures of probiotics and prebiotics and stimulate a host’s resident bacteria. They are composed of live microorganisms and substrates that demonstrate a health benefit when combined.

Scott notes that, in human trials with probiotics, none of the currently recognized probiotic species (like lactobacilli and bifidobacteria) appear in fecal samples existing probiotics.

“There must be something missing in what we’re doing in this field,” she says. “We need new probiotics. I’m not saying existing probiotics don’t work or we shouldn’t use them. But I think that now that we have the potential to develop new probiotics, they might be even better than what we have now.”

She sees great potential in this new class of -biotics.

Both Scott and Marco encouraged nutritionists to work with clients on first improving their diets before adding supplements. The -biotics stimulate what’s in the gut, so a diverse diet is the best starting point.

“Poor Man’s Viagra”

More chefs are experimenting with ‘nduja, a spreadable, fermented pork salami. ‘Nduja is packed with Calabrian chiles, giving it a kick with an underlying sweetness.

‘Nduja hails from northern Italy, dating back to either the 13th Century or early 1800s (historians dispute the date). Food experts agree ‘nduja was inspired by the French sausage andouille, typically made from pork and pig innards. Like many other fermented dishes, it’s believed to have been “born out of necessity…the cured pork product that’s resistant to spoilage was originally made using excess fat and meat trimmings left over from the butchering process.” Once all ‘nduja’s ingredients are minced together, the meat is stuffed into sausage casings, fermented for 2-5 days and then aged.

‘Nduja (pronounced en-doo-ya) is referred to as “red Nutella” and the “poor man’s Viagra” (the latter because of the belief that chilli peppers are a natural stimulant).

Read more (SBS Australia)

- Published in Food & Flavor

Reviving a Fermented Soda

Is gazoz — a Mediterranean-born mocktail made with fermented fruit and herbs — the next trending drink? It“fell out of favor for a few decades,” according to an Eater article, but chefs and bartenders in Turkey and Israel are bringing it back.

Gazoz is a flavor-packed drink that is also visually striking. It’s served packed with herbs and chunks of fruit. Chef Benny Briga (Cafe Levinsky 41 in Tel Aviv) and author Adeena Sussman have written a new book on the drink.They include numerous variations on the drink, including ones that highlights Briga’s signature seasonal fruit syrup that he says is made by “sweet fermentation.” Many of the drink recipes in “Gazoz” also include sweet-fermented spices, nut syrups and aerobic fermentations such as kefir and kombucha.

Read more (Eater)

- Published in Food & Flavor

Fermentation for Alternative Proteins

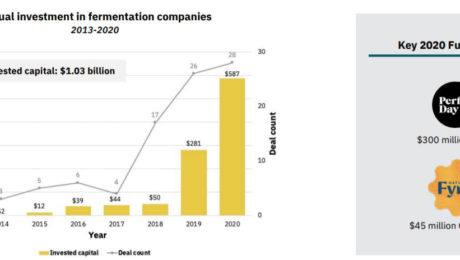

Investments in alternative protein hit their highest level in 2020: $3.1 billion, double the amount invested from 2010-2019. Over $1 billion of that was in fermentation-powered protein alternatives.

It’s a time of huge growth for the industry — the alternative protein market is projected to reach $290 billion by 2035 — but it represents only a tiny segment of the larger meat and dairy industries.

Approximately 350 million metric tons of meat are produced globally every year. For reference, that’s about 1 million Volkswagen Beetles of meat a day. Meat consumption is expected to increase to 500 million metric tons by 2050 — but alternative proteins are expected to account for just 1 million.

“The world has a very large demand for meat and that meat demand is expected to go up,” says Zak Weston, foodservice and supply chain manager for the Good Food Institute (GFI). Weston shared details on fermented alternative proteins during the GFI presentation The State of the Industry: Fermentation for Alternative Proteins. “We think the solution lies in creating alternatives that are competitive with animal-based meat and dairy.”

Why is Alternative Protein Growing?

Animal meat is environmentally inefficient. It requires significant resources, from the amount of agricultural land needed to raise animals, to the fertilizers, pesticides and hormones used for feed, to the carbon emissions from the animals.

Globally, 83% of agricultural land is used to produce animal-based meat, dairy or eggs. Two-thirds of the global supply of protein comes from traditional animal protein.

The caloric conversion ratios — the calories it takes to grow an animal versus the calories that the animal provides when consumed — is extremely unbalanced. It takes 8 calories in to get 1 calorie out of a chicken, 11 calories to get 1 calorie out of a pig and 34 calories to get 1 calorie out of a cow. Alternative protein sources, on the other hand, have an average of a 1:1 calorie conversion. It takes years to grow animals but only hours to grow microbes.

“This is the underlying weakness in the animal protein system that leads to a lot of the negative externalities that we focus on and really need to be solved as part of our protein system,” Weston says. “We have to ameliorate these effects, we have to find ways to mitigate these risks and avoid some of these negative externalities associated with the way in which we currently produce industrialized animal proteins.”

What are Fermented Alternative Proteins?

Alternative proteins are either plant-based and fermented using microbes or cultivated directly from animal cells. Fermented proteins are made using one of three production types: traditional fermentation, biomass fermentation or precision fermentation.

“Fermentation is something familiar to most of us, it’s been used for thousands and thousands of years across a wide variety of cultures for a wide variety of foods,” Weston says, citing foods like cheese, bread, beer, wine and kimchi. “That indeed is one of the benefits for this technology, it’s relatively familiar and well known to a lot of different consumers globally.”

- Traditional fermentation refers to the ancient practice of using microbes in food. To make protein alternatives, this process uses “live microorganisms to modulate and process plant-derived ingredients.” Examples are fermenting soybeans for tempeh or Miyoko’s Creamery using lactic acid bacteria to make cheese.

- Biomass fermentation involves growing naturally occurring, protein-dense, fast-growing organisms. Microorganisms like algae or fungi are often used. For example, Nature’s Fynd and Quorn …mycelium-based steak.

- Precision fermentation uses microbial hosts as “cell factories” to produce specific ingredients. It is a type of biology that allows DNA sequences from a mammal to create alternative proteins. Examples are the heme protein in an Impossible Foods’ burger or the whey protein in Perfect Day’s vegan dairy products.

Despite fermentation’s roots in ancient food processing traditions, using it to create alternative proteins is a relatively new activity. About 80% of the new companies in the fermented alternative protein space have formed since 2015. New startups have focused on precision fermentation (45%) and biomass fermentation (41%). Traditional fermentation accounts for a smaller piece of the category (14%). There were more than 260 investors in the category in 2020 alone.

“It’s really coming onto the radar for a lot of folks in the food and beverage industry and within the alternative protein industry in a very big way, particularly over the past couple of years,” Weston says. “This is an area that the industry is paying attention too. They’re starting to modify working some of its products that have traditionally maybe been focused on dairy animal-based dairy substrates to work with plant protein substrates.”

Can Alternative Protein Help the Food System?

Fermentation has been so appealing, he adds, because “it’s a mature technology that’s been proven at different scales. It’s maybe different microbes or different processes, but there’s a proof of concept that gives us a reason to think that that there’s a lot of hope for this to be a viable technology that makes economic sense.”

GFI predicts more companies will experiment with a hybrid approach to fermented alternative proteins, using different production methods.

Though plant-based is still the more popular alternative protein source, plant-based meat has some barriers that fermentation resolves. Plant-based meat products can be dry, lacking the juiciness of meat; the flavor can be bean-like and leave an unpleasant aftertaste; and the texture can be off, either too compact or too mushy.

Fermented alternative proteins, though, have been more successful at mimicking a meat-like texture and imparting a robust flavor profile. Weston says taste, price, accessibility and convenience all drive consumer behavior — and fermented alternative proteins deliver in these regards.

And, compared to animal meat, alternative proteins are customizable and easily controlled from start to finish. Though the category is still in its early days, Weston sees improvements coming quickly in nutritional profiles, sensory attributes, shelf life, food safety and price points coming quickly.

“What excites us about the category is that we’ve seen a very strong consumer response, in spite of the fact that this is a very novel category for a lot of consumers,” Weston says. “We are fundamentally reassembling meat and dairy products from the ground up.”

- Published in Business, Food & Flavor, Health, Science

Zilber on Leaving Noma for Bioscience Corporation

A sustainable food industry will be built by flavor, says David Zilber, noted chef and food scientist.

Zilber made major headlines and surprised many in October when he left his job as head of the fermentation lab at Noma for a food scientist position at Chr. Hansen, a global supplier of bioscience ingredients. Noma, a two-Michelin star restaurant in Copenhagen, Denmark, has been regularly ranked one of the best restaurants in the world. In 2018, Zilber co-authored a bestselling book on fermentation with Noma co-owner Rene Redzepi.

In an Instagram live interview last week with Al Jeezera’s Femi Oke, Zilber elaborated on why he traded an apron for a lab coat. The global food system, Zilber says, is unsustainable. Waste is prevalent, food is created with long footprints, agricultural production is shrinking, meat is heavily consumed and large corporations control the industry.

Transforming Vegetables

“What I’m trying to do in my work is to make vegetables as God damn tasty as they can possibly be by using microbes, using things that are already at our disposal, and convincing people that this might have to have a little bit of a longer inventory life while you let it ferment, while you build a stockpile, but this is the result, this is why you’ll be able to convince people why eating this way is healthy for them and the planet,” he says. “Flavor is king.”

Ingredients created by Denmark-based Chr. Hansen (the company has 40,000 microbial strains used as natural ingredients) feed 1-1.5 billion people a day. These include microbes in yogurt and yeast in beer.

“I work with them to try and make the food system more sustainable, to get more people eating vegetables,” Zilber says, adding that 30% of every calorie consumed by humans is fermented by bacteria, microbes or fungus. “No matter what we eat in the future, that’s still going to be the case. That slot of the human diet still needs some form of microbial transformation, whether it’s meat or dairy or oat milk or peas. I work to figure that out.”

It’s a different philosophy compared to the food technology many new companies are utilizing to create alternative proteins like Beyond Burger. He complimented the company for their high standards, but he says a Beyond Burger patty is not a replacement for a juicy, beef burger. People pay more for an inferior eating experience.

“At the end of that day, that will not cut it,” Zilber says. “Why does food have to be that processed to be purportedly that delicious? With some skilled tricks in the kitchen, with some ninja jiu jitsu behind the stove, you can make vegetables really, really delicious.”

Sustainable Food Systems

A sustainable food system will look much like one from 300 years ago, Zilber hypothesizes. It will be localized, where people purchase food produced close by. Modern practices of shipping ingredients and processed food around the globe are harmful to the environment.

“A truly sustainable food system looks far more decentralized than [the current one] does right now. There are [only a] very few stakeholders that are responsible for really a lot of calories,” he continues.

Oke questioned how Zilber could change a broken food system controlled by large companies when he now works at one of the major companies.

“If you want to be an idealist, that’s great, you might end up being a martyr,” Zilber says. “Sometimes you have to work within those contradictory institutions to try to do as much good as possible.”

Restaurant Industry’s Responsibility

The restaurant industry plays a part in it too, Zilber says. Workers are stretched thin, overworked, underpaid “and then extremely vulnerable in a time of crisis.” The pandemic has exposed and highlighted these problematic parts of the restaurant business.

Zilber says there are still too many restaurants. It’s hard to find good cooks, and staff is often undertrained.

“I took a step into food production myself. Maybe more of these cooks, more of these people who are passionate about food, need to consider options beyond just the restaurant setting and see value in becoming a farmer, becoming a distributor, becoming someone who decides how those calories are made because restaurants aren’t the full picture of the food system,” he continues. “There are a lot of talented people within it who know food, who understand it, who understand the human experience of what it means to make good tasting food and satisfying food. There’s other places for them to work as well.”

- Published in Business

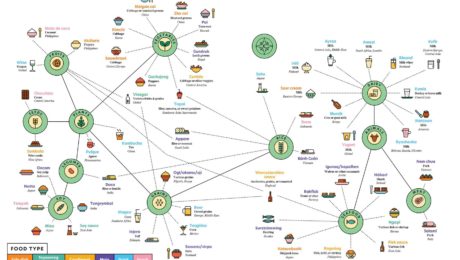

The World of Fermented Foods

In the latest issue of Popular Science, a creative infographic illustrates “the wonderful world of fermented foods on one delicious chart.” It represents “a sampling of the treats our species brines, brews, cures, and cultures around the world,” and is particularly interesting as it shows mainstream media catching on to fermentation’s renaissance. Fermentation fit with the issue’s theme of transformation in the wake of the pandemic.

Read more (Popular Science)

- Published in Food & Flavor

Creating Meat Alternatives from Thin Air?

Air Protein, a Bay-area startup, is using NASA-inspired fermentation technology to create an edible protein. The company, which recently received $32 million in funding, is the first to make “air-based” protein, farming carbon from the air with microbes.

The vertical fermentation tanks used by Air Protein combine carbon dioxide, oxygen and nitrogen with water and minerals. “The final products is a protein-rich flour that can be used just like soy or pea flour,” writes the Mercury News. “This protein flour can then be made into a plethora of delicious and nutritious meatless meat products.”

Founder and CEO Lisa Dyson discovered the NASA research while searching for new ways to recycle carbon and address the global climate crisis. She says Air Protein’s technology will “create the most sustainable meat available and significantly reduce the burden on our planet’s resources that is being cased by our current meat production processes.”

Read more (Mercury News)

- Published in Science

From Soil to Salami: Fermentation, Life and Health

Modern society needs fermentation now more than ever, as the food system becomes industrialized and unsustainable, says Meredith Leigh, farmer, activist and author. Consumers are far removed from farmers and the land, and food produced in factories hurts the environment.

“People are eating more fermented foods. The experience of food is not a quantity thing anymore, it’s more of a quality/complexity thing.” Leigh shared her insights into meat fermentation and creating a food system connected to the land and animals during a TFA webinar, From Soil to Salami: Fermentation, Life and Health.

“The punch and umami and funk is really becoming more understandable to people. That’s really promising, specifically when it comes to protein. Smaller portions, more complex flavor over big chunks of flesh that are ultimately not in service of thrift or sustainability,” Leigh continues. “My hope is that the funkier the better because we really need people to be able to stretch their palate understanding in order to get specifically meat products in a better, more sustainable, ethical situation within the food system.”

Leigh started in the food industry as a farmer, raising vegetables and animals. Concerned with how much money she was losing to the meat processing sector, she streamlined her business by opening a whole-animal butcher shop and restaurant. Leigh served only regional meats and meat products to a local audience, but found the farm-to-table business model too complicated for the general public — folks were not ready to walk into a butcher shop and buy a whole animal.

So Leigh pivoted to educating, consulting with farmers, restaurant chefs and home cooks. She also authored two books, “The Ethical Meat Handbook” and “Pure Charcuterie.” [ADD LINK?]

Charcuterie often gets overlooked in fermentation conversations because meat preservation is a “vast umbrella” of fermented and cooked meat.

“Uncooked, salt preserved meat items are very much a beautiful culmination of a lot of different culinary fermentative processes that humans harness. It very much belongs on the docket of fermented superfoods,” Leigh says.

The fermentation of meat, though, can be shocking to chefs accustomed to cooking in relatively sterile environments. When making a salami, for example, the meat becomes swollen, smelly and drippy, fermenting in a humid room.

“It’s not exactly a beautiful process. If you zip down to the microscopic level, there’s a lot of death happening, there’s a lot of engorging. It’s a sugar battle,” Leigh says. “It’s a sugar feeding frenzy and some of them are actually eating so many sugars that they’re exploding and the enzymatic soup of these explosions is part and parcel of the flavor we associate with fermented foods.”

“I tell people, ‘Close the door, it’s none of your business because you’re fermenting.’ That advice is disarming because it’s amusing. But also it’s really true. You’re in there tinkering and you sort of have control over this process, but you sort of don’t. And that’s a good thing that you’re not totally in control. You’re surrendering to nature.”

Adds Kirsten Shockey, author and educator (and TFA advisory board member who moderated the webinar): “You’re much more of a microbe shepherd. You’re trying to herd everybody, but you have no control. Each of those microbes [is] out for themselves.”

Modern consumers and even commercial fermented food producers are often far removed from farming. Leigh says that, to reclaim our food systems, we need to look at the indigenous practices that founded the sustainable agriculture movement. Commercialized food erases the land ethic and the traditional farming and fermentative processes of indigenous people, especially indigenous women.

“If we as producers, curators and knowledge bearers of fermentation, if we’re not telling that part of the story to the people really into fermented foods, we’re not doing anybody any favors. We’re just making money and putting good food out there. Really connecting people back through fermented foods is one of the more hopeful ways we have of telling that story to people who will never touch soil or slaughter a pig or any of those things,” Leigh says, adding that the best place to start sharing that story is through social media. “The popular media conversation about fermentation is not doing that. Our production of these foods or curation of these foods is not only a way to elevate health, human health or flavor, but it’s also a way of commenting on and changing culture.”

- Published in Food & Flavor

- 1

- 2