PBS Features HEX Ferments

Baltimore-based HEX Ferments was the star of the PBS show START UP. The series highlights small American business owners, chronicling what it takes to start a successful business.

During the episode, HEX Ferments co-founder Maegan Carpenter schooled START UP host Gary Bredow on ferments and gut health. She explained how the modern gut microbiome has been eroded by antibiotics, but fermented foods help to populate and repopulate the digestive system with good bacteria.

“What you’re getting essentially is a vegetable that’s been fermented in a blanket of bacteria that’s indigenious to our bodies: lactobacillus,” Carpenter explained, while Bredow sampled HEX’s seasonal Spirit Berry kombucha and Pizza Kraut sauerkraut.

A former art professor, Carpenter and her co-founder husband Shane, a former wedding photographer, never planned to start a fermentation business. Carpenter began teaching people how to use produce from their local community garden, offering tastings of the vegetables she fermented. Orders for her ferments started showing up in her mailbox. Carpenter said she thinks the demand came from “being open with people and showing people something that has been taken out of our culture for so long.”

Bredow added about modern food convenience: “It’s scary to think about if that convenience goes away, are we going to have a society of people incapable of watching food rot right in front of them.” Carpenter responded: “I think we already do.”

HEX Ferments will be expanding into a new, larger retail space later this year, HEX Superette. The space includes a kombucha taproom, small restaurant area to serve small plates, space to teach education classes and a local food marketplace. HEX Superette, Carpenter said, will “answer the question, ‘How do I eat this?’ because after 10 years of making fermented foods, we often get that question.”

Bredow concluding the episode noting that fermentation was born out of food scarcity, something today’s generation did not understand until the Covid-19 pandemic.

“Our ancestors planned for the future knowing that self sufficiency can mean the difference between life and death. Maybe it’s time to revisit the skills that allowed past generations to live with less fear and reliance on a system that always seems to be on the brink of collapse,” Bredow said. “I love what Meghan and Shane are doing. They’re not only offering up tasty and healthy foods, they’re reminding us how important it is to learn this lost craft before it’s too late…they’re offering fermentation classes. To me, this really is purpose. A focus on doing well and doing good for the world around them.”

- Published in Business, Food & Flavor

Promoting Fermentation Innovation

Several obstacles prevent the innovation of fermented foods, from the lack of scientific research to a chasm between science and industry to improving the sustainability of traditional ferments.

A third of foods consumed worldwide are fermented, totalling 3,500 products. A group of European scientists is studying how those fermented foods can drive innovation in food systems.

“There’s not a clear way to improve the unique properties of traditional fermented foods using microbial organisms,” says Vittorio Capozzi, PhD, a researcher with the Institute of Sciences and Food Production (ISPA) in Italy. “We still need innovation in traditional fermented foods.”

Capozzi was one of the presenters at a side event during the October Food & Agriculture Organization of the United Nations Science and Innovation forum. PIMENTO hosted the session. PIMENTO (which stands for “Promoting Innovation of ferMENted fOods”) launched last year in Europe, a project of the European Cooperation in Science and Technology (COST). PIMENTO aims “to place Europe at the spearhead of innovation on microbial foods” by promoting fermentation’s health, diversity and production. To achieve this goal, five working groups are structured around different fermentation topics. The groups are made up of both scientist and non-scientist fermentation experts studying and eventually implementing their findings.

Traditional ferments have “an important part of biodiversity that we cannot neglect,” Capozzi says. Fermentation provides new microbial-based solutions for a variety of foods, from plant-based ferments to alternative proteins. Innovations can improve nutrition and sensory qualities.

“In this way we are preserving biodiversity that has huge potential in biotechnology, science and innovation,” he says.

Ferments, he notes, can be protected. For example, a ferment produced in a specific geographical region (tequila in Mexico), a protected diversity, vegetable type, animal product or the human behavior used in production (Salers cheese in France).

“Fermented foods have been shaped through the centuries,” says Effie Tsakalidou, professor at the Agricultural University of Athens in Greece. “We have a lot of diversity.”

One of PIMENTO’s tasks is to create a database on European fermented foods. This list would include food types, production, consumption volume, technological parameters and legal status (like certifications).

Speaking on the health benefits and risks of fermented foods, Smilja Todorović, PhD, a professor at the Institute for Biological Research in Serbia, notes there’s a dearth of reputable, peer-reviewed studies on fermented foods.

“One of the very important things is to identify gaps in scientific evidence regarding benefits and risks,” she says.

The current studies on fermented foods are few and limited. Research does prove consuming fermented foods is correlated with overall mortality, decreased risk of diabetes, certain cancer types, high blood pressure and cardiovascular diseases. Todorović says that’s not enough.

“Unfortunately, when we look at scientific evidence to claim health properties, we can see that there are insufficient evidence. So all we have is a growing scientific interest in fermented foods and their impact on human health. However, we need to move from promising results to scientific evidence,” he says.

PIMENTO’s working groups are cataloging fermented foods’ impact on the gastrointestinal symptom, allergies, immunity, bone health and neurological projects. They also plan for projects studying fermented foods bioactive compounds, vitamin production and functionality; and fermented foods use in personalized diets.

The lack of studies prevents innovations in the field. Antonio del Casale, co-founder and CEO of Microbion, an agro-industrial microbiology company, says there is a disconnect between the scientists studying fermented foods and fermented food producers. He calls it “a valley of death.” The research on fermented foods is low, but the development of commercial resources are increasing.

“The problem is how to avoid the limitations of developing the food in this sector,” he says.

Traditions of Fermentation, Cultural Appropriation & Diversity

Cooking isn’t limited to only making the dishes of one’s ethnicity. The cultural identity of that food becomes murky when it gets transactional. Commercializing a food without respecting and honoring its history and tradition is inauthentic, damning to immigrant producers and threatens to erase traditional foods.

“Someone with more power or dominance, they can create their own kimchi – that doesn’t have any resonance to its tradition – and get it on the shelves of Wal-Mart and make it commercially successful. I don’t have that opportunity because I’m a woman, I’m Korean, I’m a minority and I’m just trying to tell the story about kimchi in my way,” says Lauryn Chun, founder and CEO of Mother-in-Laws kimchi. Chun’s kimchi comes from her mother’s recipe used in the family restaurant in California, Jang Mo Jip. “It’s my heritage of food that I enjoy sharing with Americans.”

Chun’s experience is similar to many BIPOC producers. It’s difficult for minority producers to compete with the white-owned brands that often have more money to launch a food company and receive preferential treatment by retailers for store placement.

“When you turn it into a business and you’re profiting as a company, we need to be more sensitive and more deliberate in how we give credit to people,” adds Robert Danhi, chef and co-founder of Flavor360 Solutions (and a TFA Advisory Board member)

Speakers discussed the wide range of issues related to traditional foods in a panel during TFA’s conference FERMENTATION 2022 titled “Traditions of Fermentation, Cultural Appropriation and Diversity.” Panelists included Chun, Danhi, Beverly Kim (chef and owner of restaurants Parachute and Wherewithall in Chicago), Kheedim Oh (founder of Mama O’s Premium Kimchi and TFA Advisory Board member) and Ismail Samad (founder of Loiter and Wake Robin Foods). The discussion was moderated by Josephine Wee (assistant professor at Penn State University and a TFA Advisory Board member).

Do Cultures Own Their Foods?

“There’s appropriate appropriation,” says Oh, whose Brooklyn-based kimchi brand is also based off the recipe of Oh’s mother, a Korean American. “Some of these brands, is what they’re making even kimchi? Kimchi is such a popular buzzword now. But it’s an unfair advantage when you’re competing with me and Lauryn to get your kimchi on the shelf and it’s very loosely kimchi.”

Brands are coming to retail with condiments labeled kimchi that are far from the traditional Korean condiments. They’re skimping on ingredients, like not using traditional Napa cabbage and opting for cheaper produce varieties. Though there’s hundreds of versions of traditional kimchi, some brands are veering too far to gain sales (Oh joked about a raspberry cheesecake kimchi).

“We need to change the narrative from appropriate to appreciation, celebration and preservation,” Wee adds.

Should a culture own a fermented food? Like Koreans just selling kimchi? The panel didn’t agree with that notion. But Samad points out a culture’s food is taken away from them when it’s exploited.

Through his nonprofit Loiter, Samad tackles the effects of systemic racial and economic injustice. He’s helping the residents of East Cleveland by developing successful, community-owned businesses – like Wake Robin Foods, a fermented food brand Samad purchased. Wake Robin will create ferments using produce from local, urban farmers.

“It’s black owned by black farmers so we can get some black dollars circulating in our culinary economy so they can have some freaking version of reparations for what has happened,” Samad says. “For me this is straight financial, who gets the opportunity to scale up.”

Samad says there’s an entire food system of African fermented foods “not being appropriated or appreciated in the U.S.” He hopes to disrupt the market.

“There’s an opportunity to introduce products that are owned by own by us, and by us I mean the African Diaspora,” he says.

Nuances in International Dining

Many American diners, though, are “still even at the elementary level of understanding the differences between different cultures in a diaspora,” says Kim, a former Top Contestant. “Asian cuisine is not just one monolithic cuisine.”

Some pan-Asian restaurants sell sushi (Japan) alongside kimchi (Korea) and pad thai (Vietnam), a “mish mash” of foods from different Asian countries. “We have to “continuously dig deeper to show there are nuances between the cultures,” she says.

It can be a difficult concept for chefs, too, who are trained in primarily French cuisine at culinary school. When Kim went through culinary school, a short quarter was focused on global foods, “the rest is basically Fresh cuisine.”

Ethnic food — especially Asian fare— the food is often stereotyped as cheap, “it’s a bamboo ceiling that you can’t charge high prices,” Kim says. Western diners often don’t take into account the differences in quality of ingredients or the creativity, care and time in cooking a dish. “We’ve been seen as cheaper because we’re Asian, so people question why our prices are so high.”

Chun, who grew up helping in the family’s Korean restaurant, began Mother-in-Law’s kimchi questioning why kimchi wasn’t in the ranks of specialty craft foods like fine cheese.

“From the perspective of western fermented foods, from cheeses to wines to craft beers, those are the only things people are willing to spend their money on,” Chun says. She adds she felt very proud to be the first kimchi in specialty grocery store chain Dean and Deluca.

In retail, many international food brands get placed in the ethnic aisle. But why does a sauce from an international region get placed in the ethnic aisle while spaghetti is placed in the sauces aisle?

“I’m torn over the concept of that existing,” Oh says. “We’ve been subjugated to the ethnic aisle aka the global ghetto where there’s no reason for it except the fact that I’m Korean.”

Cultural Regulatory Bias

Are there conflicts between tradition and science? Panelists shared how some health regulators don’t understand cultural ferments, causing batches of fermented food to be deemed unsafe for human consumption and thrown out.

Kim attempted to start a wholesale kimchi brand during the brand. Studies prove kimchi is made safely at a pH range of 4.2-4.5, but the regulator from the health department was told Kim legally had to keep kimchi under pH levels 3.3 to keep it safe.

“There’s so much confusion around it, I had to reach out to food scientists to clarify it, and we don’t want to get in trouble,” Kim says. She ended up cancelling the brand because securing regulatory approval was so difficult.

Oh adds: “I think there’s a big cultural bias when it comes to fermented foods. In the U.S., it’s either the food is 100% clean scrubbed and pasteurized or it’s not – and the not is dangerous and dirty. Where fermented foods predates modern electricity and modern science, there’s a reason why it’s safe because it works out that it’s a very safe food because, through the lactic acid fermentation, it lowers the pH and that helps preserve the food.”

- Published in Business, Food & Flavor

Upcycling & Zero Waste

Fermentation is a powerful culinary tool for upcycling.

During the Upcycling and Zero Waste session at FERMENTATION 2022, six fermentationists with diverse backgrounds in the industry shared how they’re using fermentation to reduce food waste.

“As a chef, we are constantly chasing these depths of flavors and things that you can’t get in regular cooking applications or techniques. Fermentation opened up a whole new world of flavor,” says Jessica Alonzo, a fermentation specialist and owner of small batch ferments company Native Ferments in Texas. “We were looking to enhance diner’s experience and fermentation did that.”

The panelists from all over the world included: Alonzo, Jeremy Kean (chef/owner of Brassica Kitchen), Mac Krol (CEO/founder of Mac Ferments), Richard Preiss (cofounder and brewing scientist at Escarpment Labs), Michelle Ruiz (CEO/co-founder of Hyfé Foods) and Ismail Samad (founder of Loiter and Wake Robin Foods).

Aiding farmers

Alonzo consults with area restaurants to build unique larders. She helped create the fermentation and whole food utilization program at Petra and the Beast as the former sous chef. Fermenting the restaurant byproducts helped the restaurant eliminate food scraps, cut down on food cost and partner with farmers.

Up to 40% of food grown in America is thrown away, according to the U.S. Department of Agriculture.

“I got into zero waste and upcycling through relationships with farmers, seeing how much was wasted at the farm level,” says Samad, who also co-founded and was executive chef at The Gleanery in Vermont. “The Gleanery existed for the last 12 years to provide a very clear safety net for farmers not selling their stuff at the farmers market.

Samad admits he didn’t know much about fermentation when he first started, “We just knew we didn’t want to keep wasting food.” By fermenting the kitchen scraps, “we’re making sacrifices that big food won’t do.”

Exploring Science

At a scientific level, Preiss at Escarpment is looking at upcycling “through a microbiologist lens.” Preiss said he began upcycling when he realized the current food system is unsustainable in a linear economy.

“There’s a lot of opportunity for creating circular food economies to not only reduce waste but help every single stakeholder involved in this process make more money, pay people more, create jobs, be more profitable and ultimately stay open as part of the sustainability discussion,” he says.

Restaurants are often leading upcycling and fermentation conversations – “many people know about fermentation because of restaurants.” But Preiss says the craft beer industry is becoming a leader in the upcycling movement because, today, they’re in many neighborhoods. “They have a really cool platform to communicate new ideas around food innovation.”

Escarpment is exploring interesting ways to use spent grains from beer. Currently, they’ve created a way to make seasonings. Brewers use those seasonings in their menu dishes, a novelty that gets customers excited about pairing a beer with a dish seasoned with that craft brew’s spent grain.

“There’s a lot of opportunity in that grain, there’s still a lot of nutritional quality,” Preiss says. “Through fermentation, we unlock new possibilities.”

Hyfé Foods is also utilizing waste. They’re taking the discarded sugar water (typically used in beverage production) and, through fermentation, repurposing it in mycelium flour. Mycelium is a type of mushroom. Hyfé’s proprietary biotechnology makes a protein-rich, low carb mycelium flour in a carbon-neutral, affordable process.

“Often when a manufacturer makes a product, the lifecycle being considered ends at the door. We’re often not measuring the greenhouse gas emission impact, the wasted sugar water – that goes down the drain,” says Ruiz. Food manufacturers pay a hefty fee to get rid of waste water. “We’re really excited about the position that upcycling puts us in, not only from a cost standpoint but also we’re creating a really nutritious, low cost food.”

Upcycling Barriers

Upcycling is not without its challenges.

Kroll at Mac Ferments specializes in koji. He recently created shoyu made with used coffee grounds, koji, water and salt – an excellent choice, he says, for a restaurant that likely throws out pounds of coffee grounds at the end of the night.

“It is obviously nice to create added volume from leftovers, it tightens the whole supply chain,” Kroll says. “But also there are risks of potentially overproducing just to create extra waste. You have to be careful what you’re doing because you’re dealing with enzymes – and we don’t see microbes.”

Fermentation, he says, should be utilized for quality, not quantity.

“If every dish has something fermented, a regular customer might come home starving,” Kroll adds.

Preiss sees collaboration as a major challenge because creating a circular, upcycled system involves multiple stakeholders sharing their waste products.

“Upcycling can’t be done in a silo, you need collaboration, and getting people that have the different pieces of the puzzle together to make it happen is the biggest challenge,” he says.

Samad, meanwhile, says scaling is a hurdle. “There are opportunities for investments around upcycling, but there’s a ceiling where this culture or ethos can be sustained.”

Educating customers, too, can be tricky. The public consuming the product or dish needs to understand what is upcycled. Servers, as the mouthpiece to diners, must taste and know a dish to communicate its elements. Chefs must detail to servers where ingredients were sourced, how long the food was aged and what was cross utilized, Alonzo says.

Panelists said the public is excited about the new taste experiences with upcycled food – but they’re also more curious about the science behind it.

“Folks come into Brassica for that fermentation program and are so interested and hungry for that knowledge from the science community,” Kean says. “And then theres folks that just want to eat and say ‘What the fuck was that?’ I think it’s a mixture between the two.”

“The education around all this stuff is growing,” he adds. “I see the culinary world and science world getting closer and closer together and I think that’s the right direction.”

- Published in Food & Flavor, Science

Making Resilient Brands in Economic Downturn

Natural food sales continue to balloon since the Covid-19 pandemic, but food producers should not get comfortable yet with the wellness-minded consumer. Brands need to brace for what’s coming. With inflation, supply chain challenges and a looming recession, brands must remain resilient in the changing economy.

“Even in the face of a recession, growth is continuing,” says Carlotta Mast, senior vice president of New Hope Network (a division of Informa PLC), which produces Natural Products Expo West. “People are not expected to ‘trade down’ from health.”

Sales in the natural and organic products industry grew 7.7% in 2021 to reach $272 billion. Estimates put the industry at hitting $300 billion in sales in 2023. The stats were presented during the State of Natural & Organic Industry presentation (presenters pictured) at Expo East, the natural products show hosted in Philadelphia this year. More than 1,100 brands exhibited at the expo, many capitalizing on the growing wellness and functional foods trends.

Functional food and beverages – the subcategory where fermented products reside – continues to be a bright spot in the natural products space. Functional food and beverage sales are driving 70% of natural product sales. Functional sales grew 8.3% to $83.7 billion in 2021, with sales on track to reach nearly $100 billion by 2024. Functional food and beverage – like kombucha, drinking vinegars and probiotic sodas – is the top growth category in functional.

“This is truly a hot spot for our consumers,” Mast says. “People are expecting their foods and their products to have real health benefits.”

Natural products are outpacing growth of conventional products. Over 60% of CPG brands launched in the last year have a health and wellness focus. Natural products are also leading sales in all retail channels – natural, regional grocery, conventional multi-outlet and convenience stores.

“Everywhere we buy, were all buying more natural products and it’s outpacing mainstream growth which is really encouraging as we go forward,” says Kathryn Peters, executive vice president at SPINS (a data provider for natural, organic and specialty products).

Of note, online sales of CPG have returned to pre-pandemic levels, proving brick and mortar sales still reign supreme. Natural products are purchased online at two times a higher rate than conventional products, proving a multi-channel strategy is needed for brands.

- Published in Business

The Flavor Whisperer on Fermentation

Flavor is much more complex than just taste. Flavor can be collected, extracted, infused, created and transformed. And, in a billion-dollar flavor industry devoted to putting flavors into processed foods, fermentation is the oldest and most natural flavor creator, developing new flavors at a molecular level.

“Fermentation as a flavor creation process in collaboration with microbes, there’s almost no limit to how you can apply it and use the ingredients around you and have a more flavorful palette to work from,” says Arielle Johnson, PhD, a flavor scientist, gastronomy and innovation researcher and co-founder of the Noma Fermentation Lab.

A food chemist dubbed the flavor whisperer, she works with restaurants on innovating dishes and cocktails. She researches how flavor is perceived and is writing a book on her studies, Flavorama. Her work comes together in “all things science and cuisine have to say to each other.”

This week Johnson shared her insights into flavor and fermentation as a guest lecturer at Harvard University’s Science & Cooking series.

Taste & Smell Receptors

Flavor can be quite complex – Johnson calls it a black box.

There are five primary tastes: sweet, sour, salty, umami and bitter. Each taste evolved to ensure humans get basic nutrition. We use sweet foods for the energy in sugar, sour ones for vitamin C from fruit and fermented foods. Salty foods provide the essential mineral sodium. We seek umami foods for the taste of glutamine, an amino acid in proteins and fermented foods.

But bitter, Johnson points out, doesn’t sense one thing. It senses multiple molecules that are potential toxins for us. This is why bitter is called an acquired taste.

Smell is Johnson’s favorite part of the flavor profile. In order to taste, we must smell, too. Molecules land in the olfactory receptors in the nasal cavity and help activate taste. This is why food is tasteless if you plug your nose while eating. But the back of the throat is also connected to the nasal cavity, so the throat becomes “the secret backdoor” for sensing flavor.

While there are five major tastes and four receptor areas on the tongue, there are 40 billion smellable molecules and 400 receptors for smell.

Supertasters vs. Nontasters

Taste and smell, she detailed, help us understand how fermentation works.

The population can be divided into supertasters or nontasters. During her presentation, Johnson had the audience put a strip of filter paper on their tongue. The paper included a harmless bitter molecule phenylthiourea (PTC), but only roughly half the class could taste it. This group are supertasters – the group who could not taste the PTC are nontasters.

She explained everyone has different density of their taste buds. Supertasters have more taste buds, so more taste receptors signals are sent to their brains. This has culinary implications. Because their sense of taste is more sensitive, flavors are intense and supertasters have a less adventurous palette. Meanwhile nontasters have dulled senses, so it takes a lot of flavor to activate taste.

“The good news for supertasters is that fermentation is usually salty and sour and often umami – all of which counteract bitterness,” Johnson says. “Fermentation is a way to create new flavors but also transform ingredients.”

Fermentation as Flavor

Though “microbes are opportunistic” and pop up in foods whether planned or not, fermentation can’t be forced, Johnson says. When making a sauerkraut, for example, microbes don’t need to be added. Fermentation works with what’s on the surface of the cabbage and on the producer’s hands.

Salt is key in fermentation as a flavor additive, a preservation element and a safety measure. Salt filters out bad molds and avoids letting a ferment spoil. Other factors “dial in the flavors in this molecular flavor creation process,” she says, like the correct ingredients, temperature control and humidity.

“We’re really excited about microbes and fermentation,” Johnson says. “In this process of this exponential growth that microbes do, they’re eating things, they’re getting energy, but they’re also running their regulator metabolism. So there’s all these waste products that are not very significant to the microbes, but that can create a lot of interesting flavor complexity.”

- Published in Food & Flavor, Science

Fermented Flavor Development in Restaurants

In the last decade, fermentation has taken center stage at fine dining restaurants. How do owners and chefs develop and maintain a fermentation program for their kitchen?

An all-star team of U.S. chef-owners at FERMENTATION 2022 shared their successes and failures in developing fermentation-focused kitchens. Speakers included: Sean Brock of Audrey Restaurant in Nashville, Jeremy Kean of Brassica Kitchen in Boston and Misti Norris of Petra & the Beast in Dallas. Jori Jayne Emde, chef, educator and owner of Corner Office in Taos, New Mexico, moderated the discussion.

The chefs all focus on whole food utilization, aiming to eliminate food waste in flavor-packed dishes. Fermentation is key. Food scraps that would otherwise be thrown out – stems from produce, coffee grounds or animal bits – are fermented and reinvented in flavorful, unique dishes.

“By reusing the product in different manipulations over and over again, this type of program can really develop branding potential over time,” Emde says. “The process of bringing several lives to one product puts one’s fingerprint on the cuisine, so the restaurant expresses its own terroir.”

In-House Fermentation

Core to developing a restaurant fermentation program is assigning someone to oversee the process. Who will track the start dates, monitor pH levels and control filtration?

Emde, who formerly ran Fish & Game in New York’s Hudson Valley, quickly learned at the restaurant “you can’t just have a multitude of chefs handling it…ferments are alive and require being nurtured and cared for.”

Brock agrees, noting some restaurants have their chef de cuisine or sous-chef head up fermentation efforts. “But the reality is they have so much to do already.”

“It’s critical to have someone dedicated to the program,” Brock says. “When you’re having to build such a renegade operation, the biggest challenges are keeping up with inventory and monitoring each ferment.”

Audrey hired a fermentation specialist in 2014, Elliot Silber. He has a chemistry degree and “understands fermentation at a completely different level,” Brock says.

“I still can’t believe we have someone in charge of fermentation,” he adds. “Now, we put fewer things on the plate with a bigger impact. I get to finally produce food I would consider minimalist.”

Brassica Kitchen takes a different approach to their fermentation program – a food map.

“We’ve been running fermentation forward cuisine for about 10 years and, in that 10 years, we’ve gone through a lot failure and chaos and really kind of developing things as we go, to changing the menu everyday to coming in long before service to staying long after to doing inventory and plug and play with them. We hit a wall,” Kean says. “We’ve found ourselves looking at over 100 misos and going ‘What the fuck do we do with this?’”

The kitchen’s food map is a shared document where the chefs outline how to utilize every byproduct. It’s been Brassica’s most effective menu-planning solution. “This food map has solved a lot of the problems and created a box of creativity we can really thrive in,” Kean says.

Health Department Woes

When Brock launched his first fermentation program at Charleston’s Husk restaurant in 2010, “ironically our biggest challenge was the health department,” Brock said. “They would make us throw food away.”

Health department officials – many who had no idea what fermentation was or its inherent safety – would immediately issue violations for any food sitting on a counter at room temperature, a normal process for fermenting foods or beverages. Husk maintained a makeshift lab on the roof of the restaurant hidden from officials, and staff had a code word for when the health department would come to the restaurant.

Norris recalled instances where inspectors would pour bleach on their fermented food products or throw their meat in the trash.

“It’s hard because we’ve taken the time to learn and be knowledgeable about how to keep these foods safe. And then someone comes in who is supposed to be keeping people safe but has no knowledge of food and we’re trying to make food healthier and keep it more dynamic and sustainable,” Norris says. “It’s frustrating when you put so much of yourself and your philogosphy into the food.”

Audience Acceptance

Today – as fermentation is featured regularly in food, health and science news – diners are eager to eat unique, fermented dishes. This hasn’t always been the case. Even today,diners need to trust a restaurant before they will buy dishes experimenting with fermentation. Norris notes, when Petra and the Beast first opened, fermentation was not a food trend in Texas. Residents had not grown up with a food culture of eating and preserving wild food.

“It definitely did not happen overnight,” she says. “It took a lot of educating and reassuring people that these things are delicious and they are a little uncommon, a little different. It’s something that took time and effort to understand what we were doing with full utilization and sustainability.”

Kean, too, said it took time at Brassica.

“We’d be using all these (fermented) products and I wouldn’t even mention it on the menus,” he said. “The trust was built over all these years and until we could really start speaking on it.”

Eliminating food waste was mentioned as fermentation’s gateway of acceptance for diners.

Food Waste into Food

Brock says the goal at Audrey is to find 10 uses for every seasonal, region-specific ingredient. For example, last year they received candy roaster squash from a local farm and served it in different forms in dishes throughout the fall season. But they also fermented it and will be serving it again this year.

“We don’t create dishes and then get the ingredients,” Brock says, “the ingredient fuels the dish.”

The kitchen at Audrey is full of glass-encased ferments, each organized by parts of the tongue.

Brassica has found success in utilizing food waste by creating delicious dishes that are “black holes for the extra stuff” Kean says. For example, they serve a fried rice dish using sticky rice from the day before with fermented vegetables. The dish is popular, low cost and “encourages little things that can be vehicles in a dish.”

“It’s been inspiring over the years to find a use for the byproducts, then the byproducts become so important that you have to then buy the byproduct,” he says. “It’s happened to us over and over again.”

Petra and the Beast focuses on whole animal utilization. By being sustainable and “hyper-seasonal,” Norris says, Petra is “creating food with the most depth, creating food that’s not just one note.”

“I ask myself and the team ‘Well, what should we do with it? Is there a better use for it? Is there a sour brine or can we make a salt out of it and use it on that same vegetable next season?’” Norris says. “If you really truly understand why a flavor profile is developing in a certain way, you look at everything else differently.”

- Published in Food & Flavor

Fermentation for Global Health

Though scientists and environmentalists have warned about the dangers of increased meat consumption, Americans’ appetite for it is not slowing down. The last three years marked the largest amount of meat produced on record.

“People know about the harms of industrial agriculture, but people eat more and more and more meat,” says Bruce Friedrich, CEO of the Good Food Institute (GFI). “It’s an inextricable rise despite more and more attention to the issues. The vast majority of people are just not going to apply ethical considerations to their food choices.”

Fermentation, Friedrich declares, can be part of the solution. “Fermentation can be so powerful for global health, climate and biodiversity,” he says.

Friedrich spoke at FERMENTATION 2022 on alternative protein innovation. GFI, a nonprofit, aims to accelerate the innovation of fermented, plant- and cell-based alternative meat. But the young, rapidly-growing alt protein industry faces major obstacles in scaling, regulation, pricing and consumer acceptance. Friedrich told a room of professional fermenters at the conference to consider shifting to a career in alternative proteins.

“Anyone involved in fermentation, you have the expertise in knowledge. It’s cross-applying the skills and interest in your professional life into this new field,” he says. “One of the significant barriers for all the companies doing this is talent, which is to say – you.”

Global Agriculture Crisis

Friedrich does not mince his words: we’re on the precipice of a major environmental and health crisis if we don’t reduce meat consumption.

Mass producing meat is “extraordinarily inefficient.” Huge amounts of crops are grown to feed livestock so humans can then eat the animals.. “We have been using an antiquated method to produce meat for 12,000 years,” Friedrich adds.

Internationally, 4 billion hectares of land are used for agriculture – 3 billion are for grazing livestock or to grow their food. It takes 9 calories of feed to produce 1 calorie of chicken; 40 calories to produce 1 calorie of beef.

“This is an incredibly inefficient way to try and feed the world,” Friedrich says.

And it’s getting worse. By 2050, global meat consumption is projected to increase – conservative estimates say 50%, while others go as high as 260%.

Animal agriculture also is thought to be a major contributor to global climate change and a major factor in deforestation. Livestock are pumped with antibiotics, creating resistance in humans that consume that meat.

Future of “Meat”

The answer isn’t necessarily a world of vegetarians – it’s to change traditional meat.

Friedrich compares the situation to renewable energy and electric vehicles. For decades, government leaders have preached reducing fossil fuel consumption. But, as populations have risen, so has energy consumption.

“You are not going to convince people to consume less energy,” he says. “What you need to do is replace fossil fuels with renewable energy.”

Similarly with meat, there cannot be a meatless world. “This is innovation focused, it is not about behavior change,” he says.

“GFI when we started, we were talking about disrupting animal agriculture. We very quickly realized our hope is to transform industrial animal agriculture,” he says. “Things will happen a lot more quickly if we have the major corporations on board.”

GFI is “enthusiastically working with the biggest companies in the world:” JBS, Tyson, Smithfield, Cargill and BRF, the five largest global meat producers.

The aim is not to regulate big agriculture or stop subsidies. GFI hopes to open access into the science behind alternative proteins, incentivize the private sector to continue R&D and encourage government funding.

“The same sort of cash breaks that allowed Tesla to be successful should apply to Nature’s Fynd and Impossible Foods and others if they want that money,” Friedrich says, listing two major companies in the alternative protein industry. “Our global battle cry is that governments should be funding alternative proteins.”

Food Trifecta

By not gatekeeping alt protein technology, Friedrich says GFI is helping perfect the process of giving consumers the exact same meat experience, but using plant- or cell-based meats. People want the food trifecta, Friedrich says: Is it delicious? Does it fill me up? Is it reasonably priced?

Fermentation is a booming sector in the alternative protein industry. It is split into three categories: traditional fermentation using lactic acid bacteria, yeasts or fungi; biomass fermentation which involves naturally occurring, protein-dense, fast-growing microorganisms; and precision fermentation, which uses microbial hosts as “cell factories” to produce specific ingredients.

Data from GFI found, of the alt protein startups utilizing fermentation, 45% use precision fermentation, 41% use biomass fermentation and the remaining 14% use traditional fermentation.

GFI recently hired two fermentation scientists, and their studies are already suggesting biomass and traditional fermentation will have better environmental numbers than plant-based meats. Fermentation is also a more powerful process than plant-based meat applications because fermentation can replicate precise fermentation proteins. And although traditional fermentation is the smallest part of the fermented alternative protein category, GFI sees it growing because of its ability to produce appealing flavors..

“Traditional fermentation can be an absolutely essential element to get meat to taste the same or better or cost the same or less,” he says.

“The plant based and fermentation products, they’re just getting started. The idea of competing with industrial animal meat has been around for (snaps his fingers) that long. The products are just going to improve and improve and improve.”

Does Organic vs. Conventional Matter for Fermented Foods?

Organic food is considered by some to be healthier and more nutritious than its conventional counterpart. But what about when that food is fermented? Does organic vs. conventional matter?

A new study reveals some surprising results: when it comes to fermented foods, “the quality of organic food is not always better than conventional food.”

Organic vs. conventional agricultural production is a hotly debated topic – some reports indicate organic food is more nutritious, but other research suggests the nutritional differences are not significant. Meanwhile, fermented foods are scientifically-proven to include higher nutritional value. “During fermentation, the concentration of many bioactive compounds increases, and the bioavailability of iron, vitamin C, beta carotene, or betaine is also improved,” the study notes. Fermented products also “inhibit the development of pathogens in the digestive tract.”

Researchers at the Bydgoszcz University of Science and Technology in Poland questioned whether fermenting organic food would change its nutritional output versus using conventional food. Their results were published in the journal Molecules.

Analyzing fermented plants (pickles, sauerkraut, beet and carrot juices) and dairy (yogurt, kefir and buttermilk), researchers measured the vitamins, minerals and lactic acid bacteria in the items. They compared using organic ingredients in one group to products made from conventional ingredients.

“Research results do not clearly indicate which production system–conventional or organic–provides higher levels of bioactive substances in fermented food,” the study reads.

Results were mixed. Lactic acid bacteria – the good, healthy kind – were higher in organic sauerkraut, carrot juice, yogurt and kefir. Organic kraut and pickles produced more vitamin C than conventional versions. And calcium levels were higher in yogurt made with organic milk.

But, interestingly, lactic acid bacteria levels were higher in conventional pickles and beet juice. Conventional beet juice also had five times more beta-carotene (vitamin A).

Read more (Molecules)

Cultured in Chicago: Highlights of FERMENTATION 2022

Science met the culinary arts in Chicago, at the first in-person conference of The Fermentation Association (TFA), FERMENTATION 2022. Over 200 food and beverage professionals from 15 countries Participated in four days of programming.

“There’s no denying that fermentation is having a moment – and that’s a wonderful thing that more and more people are aware of fermentation and interested in fermentation – but it’s really important to keep saying fermentation is not a fad, fermentation is a fact,” said Sandor Katz, fermentation author and educator.

Katz was the opening keynote speaker at FERMENTATION 2022. The nearly 50 experts and thought leaders who presented included Dan Saladino (BBC journalist and author of Eating to Extinction), Kirsten Shockey (author, educator and co-founder of The Fermentation School), Bob Hutkins (food microbiology professor at University of Nebraska and founder of Synbiotic Health), Sharon Flynn (founder of The Fermentary in Melbourne, Australia), Bruce Friedrich (co-founder and executive director of The Good Food Institute), Maria Marco (food science professor at University of California, Davis) and Sean Brock (chef and owner of Nashville’s Audrey Restaurant).

The conference comes as sales of fermented foods and beverages continue to rise. Fermented products grew 7.1% in the last year, according to SPINS LLC, a data provider for natural, organic and specialty products that also presented at FERMENTATION 2022.

Though Katz taught his first fermentation workshop in 1998, he’s seen “a building interest in fermentation” in the last decade. Each year since 2011, “someone says the food trend of the year is fermentation.”

“Usually I end up being a cheerleader for fermentation, encouraging people who somehow think that fermentation is an alien process, that there’s something scary about it,” he said. “I mostly reassure people that they’ve been eating products of fermentation almost every day for their entire lives, that these are processes that their safety has been proven by their endurance over time. But you all don’t need to hear that. I am speaking to the converted here.”

Where Science Meets Industry

TFA aims to fill a niche in the world of fermentation. There are plenty of DIY fermentation festivals, food and beverage industry conferences and trade shows. But TFA connects science and industry.

Attendees at the event included an array of professionals involved in fermentation – producers, retailers, chefs, scientists, researchers, authors, suppliers, educators and regulators. The conference revolved around three tracks: food, flavor and culture; science and health; and business, legal and regulatory. The group of passionate fermenters in attendance uniformly expressed their excitement and delight to learn from experts in different disciplines.

“This unique conference had the most diverse attendees as it included chefs, scientists and more,” said Glory Bui, a graduate student researcher at the University of California, Davis. “It was nice to network with those who were and were not in academia to hear different perspectives in the fermentation industry.” [Bui won the student poster competition with her research on how fermented dairy products can affect gastrointestinal health.]

Producers made up over 40% of attendees and ran the gamut from small to large scale. Sash Sunday, founder and fermentationist behind OlyKraut in Olympia, Wash., said she’s been searching for such a fermentation conference since starting her brand in 2008.

“I really appreciate getting to spend time getting to know other fermenters, hearing about people’s creative processes and experiences in the field,” Sunday said. “I really loved all the tastings and spending time with people who really think about the flavors in fermented foods.”

Niccolo Fraschetti, owner of Alive Ferments, said networking was one of his favorite parts of the conference.

“There were people there that were superstars of fermentation to people making kimchi in the bathtub,” Fraschetti said. “It was such a cool merging of fermentation.”

Fraschetti officially launched Alive Ferments in March and said he never expected the brand to grow so fast, so quickly. Alive Ferments currently is sold in 25 stores in the San Diego area. At FERMENTATION 2022, he brainstormed ideas with attendees and speakers.

“Usually I feel like in these situations, everyone is tight-lipped and doesn’t want to share (business secrets),” he said. “But everyone was a really embracing community and willing to share their knowledge. There was no competition between the peers that were at the conference.”

Connecting with others in the industry was a highlight, too, for Suzette Smith, founder of Garden Goddess Ferments and Pick up the Beet in Arizona.

“I loved that like minds were able to come together sharing similar passions,” Smith said. (I also loved “learning what’s new in the promotion of fermented foods.”

Gregory Smith, an independent chef based in Pittsburgh, said he “drove back from Chicago with my mind racing about all the things I learned.” He said the various chefs who spoke at the conference – like Flynn, Brock, Ismail Samad of Wake Robin Foods, Jessica Alonzo of Native Ferments, Misti Norris of Petra and the Beast and Jeremy Kean of Brassica Kitchen – inspired him to dive into upcycling.

“I’m excited about the way they made me look at food waste in the kitchen space and how to help utilize waste and taking excess product and converting it into something tasty,” said Smith, who runs his independent culinary service Thyme, Love & Culture with friend Romeo Kihumbu.

Karen Wang Diggs, founder of the ChouAmi fermentation device, spoke at the event in a session on fermenting with medicinal plants. She said it was “an honor” to speak at FERMENTATION 2022.

“I got to hang out with a bunch of really cool, ‘cultured,’ fermenting people – and the presentations were fabulous,” she said.

Added Neal Vitale, executive director of The Fermentation Association: “It was a privilege to have a stellar lineup of speakers. It was great to get to get together at last and explore so many aspects of fermentation.”

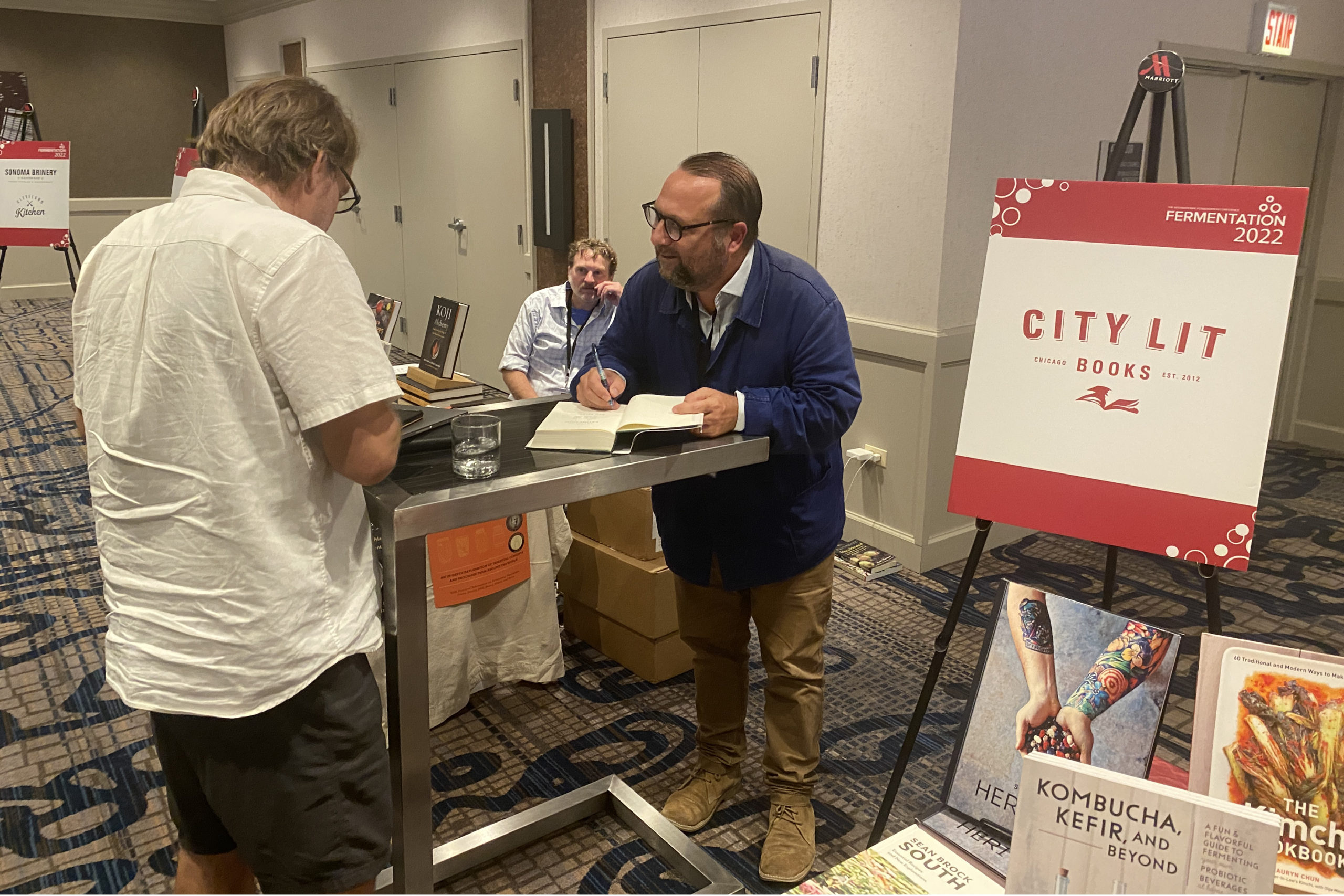

Focus on Food

Other events at the conference included: a dinner with a fermentation-focused menu prepared by Rick Bayless, chef and restaurateur; a mezcal tasting with Lou Bank, founder of SACRED and the Agave Road Trip podcast; a craft beer and chocolate pairing with Long Beach Beer, Bread and Spirits Lab; a flavor analysis workshop with Sensory Spectrum Inc.; a screening of Ed Lee’s film Fermented (complete with buttered popcorn!); and multiple book signings.

Bayless, the James Beard Award winner who runs multiple Chicago restaurants, mingled with conference attendees during the dinner. He said he and his staff enjoyed the challenge of putting something fermented in every course.

“This is the first time we’ve done a meal that is so heavily fermented,” he said, “and we had a lot of fun doing it.”

Courses included a fermented corn masa tamal, beed with a fermented black bean sauce made with black bean miso and Oaxacan pasilla chile, smoked yellowfin tuna in a broth of tejuino (fermented corn drink), and chocolate from Tabasco, Mexico, with tepache (fermented pineapple) sorbet .

“I was at a conference with Sandor Katz years ago and I talked to him about making black bean miso, and now I get to serve it to him,” Bayless said.

The Fermentation Association was started in 2017 as the brainchild ofJohn Gray, then the owner of Bubbies Pickles. His goal was simple – to bring together everyone in the world of fermentation. Today, TFA circulates its biweekly newsletter to nearly 14,000, is followed by over 11,000 on Instagram and will next develop its presence on LinkedIn. The Association is run by a small staff and a 22-member Advisory Board, including six Science Advisors.

FERMENTATION 2022 was originally planned to be a May 2020 event, but obviously postponed due to Covid-19. A virtual FERMENTATION 2021 was held in November 2021. TFA will announce plans for 2023 and beyond in the coming months.

- Published in Business, Food & Flavor, Health, Science