Diversifying the Spirits Industry

The fast-growing, Tennessee-based whiskey brand Uncle Nearest, run by Fawn Weaver (pictured), has created a $50 million investment fund aimed at helping minority-owned spirits businesses.. Black-owned spirits brands are prioritized for investment dollars, followed by those with a founder who is female and/or a person of color.

“I am looking for the brands that have the ability to be the next Uncle Nearest,” Weaver said. “What that means to me is, they are not building to flip, they’re not building to sell. They’re building to create generational wealth.”

When Weaver began Uncle Nearest and wanted to consult with a Black master distiller, she found “the overwhelming whiteness of the world of American spirits.” Her whiskey brand is named after an expert distiller named Nathan “Nearest” Green, who was born into slavery and mentored a young Jack Daniel. Last summer, Uncle Nearest and Jack Daniel’s started a $5 million initiative to bring more Black entrepreneurs into distilling. The response was so great that Uncle Nearest began its own initiative. It’s called Black Business Booster, with the intent to help 16 companies.

“It’s not that people of color don’t have an interest. It’s that we find that they have no path of entry into the industry, no connections where others may,” says Margie A.S. Lehrman, the chief executive of the American Craft Spirits Association. “It’s a very, very tough industry to break into, and if you’re a woman or a person of color, it’s even harder.”

Read more (The New York Times)

- Published in Business

Artisanal Agave Spirits

Agave spirits are quickly becoming sought-after alcoholic beverages. Hearty desert plants, agaves spend years or even decades developing indigestible carbohydrates that can be hydrolyzed for fermentation, resulting in spirits like mezcal.

“We’re at a golden age of agave spirits right now,” says Lou Bank, cohost of the Agave Road Trip podcast. Bank and cohost Chava Periban shared the centuries-old fermentation processes used to create mezcal in the TFA webinar Artisanal Agave Spirits.

Adds Periban: “The beautiful thing about mezcal is we want diversity and you can use any agave under the sun to be able to make mezcal, which makes this category probably the most intensively diverse category in the spirits world.”

Tequila vs. Mezcal

Tequila and mezcal are both spirits distilled from fermented agave. But tequila can be made only from the blue Weber variety of agave and is made by steaming the agave’s heart (pina) in above-ground ovens. Mezcal can be from any of 30 types of agave and is made by cooking the agave in underground pits lined with lava rocks.

As the market for tequila grew, the term “tequila” was declared intellectual property of the Mexican government in 1974. Extensive regulations were established that, among other things, required tequila — formerly considered a regional type of mezcal — to come from only a specified area of Mexico.

Regulations for mezcal weren’t established until 1994, when it received its own Denomination of Origin. Similar to how champagne can only be made in a specific part of France, mezcal can only be made in nine of Mexico’s 32 states.

Periban and Bank point out a major issue with this certification process for mezcal. It ostracizes rural mezcaleros who may not have the money for certification or may not reside within the geographical boundaries.

“A lot of the communities and the traditions that nourish this nostalgia and this beauty of mezcal, they cannot use this word anymore to name their own spirits, the same spirits that they have been producing for centuries in their communities,” Periban says.

Adds Bank: “We love the flavors, but we are very much about preserving the process and in preserving the process, the number one ingredient in the process are the men and women who make the spirits.”

Bank runs a non-profit, SACRED (Saving Agave for Culture, Recreation, Education and Development), that helps improve lives in the rural Mexican communities where heirloom agave spirits are made.

Wild Fermentation of Agave Spirits

Tequila is made similarly to most alcohol — the producer pitches in a yeast to eat the sugar, picking a specific yeast for the desired flavor.

On the other hand, agave spirits such as mezcal and pulque are made in open air fermentation vats. Wild yeasts off nearby fruit trees change the flavor.

Bank estimates only 1 out of every 100 different commercial tequilas is made using pre-industrial, heritage processes. Mezcal, meanwhile, is just the opposite, with 1 in 100 bottles made using commercialized techniques.

“As the world gets more interested (in mezcal), you’re going to see more industrialization and you’re going to see less and less of this beautiful handmade stuff.”

Mezcal’s flavor palate varies by region, the agave type and the processing. Most mezcal is made and sold locally, to neighbors for weddings and religious festivities.

“If you’re making mezcal, you’re not just selling the product. You’re selling the drink that’s going to be part of their most important days of their lives,” Periban says.

Artisanal drinks with natural ingredients are on the rise, especially in America. Mark McTavish, president of 101 Cider House and co-founder & CEO of Pulp Culture (and TFA Advisory Board member), doesn’t see this trend slowing.

Mezcal, he says, will aid growth in the category, as it’s an alcoholic beverage that, instead of chugging, you sip to taste the complexity of the flavors.

“I really love fermentation and what it gives to a beverage, and I think it’s way more than just alcohol,” McTavish says. “There’s just such a richness there to the connection to a sense of place and a people behind it…that’s why fermentation is so beautiful.”

- Published in Food & Flavor

Traditional Finnish Sima

On May Day in Finland, Finns toast the start of spring with a traditional fermented drink called sima. Made with water, sugar or honey, lemon and yeast, the non-alcoholic sparkling beverage is enjoyed by adults and kids. And, as foraging continues to boom in Finland, people are adding wild foods and spices to their sima. An article in BBC Travel details the drink’s history and how it took over two centuries for sima to transition from a high society beverage to a traditional drink for the working classes.

“The reach of sima also extends beyond the festivities. Young students learn to ferment sima in schools; restaurants offer sima on their Vappu (May Day) menus alongside herring, potato salad and sweet pastries; and big breweries bottle and sell their own versions of the drink. Each spring, shop shelves fill with varieties of sima, and newspapers review the best brands. Furthermore, artisanal food culture has turned homemade sima into a trend, with creative home brewers experimenting with new flavours ranging from spruce to cucumber to rhubarb.”

Read more (BBC Travel)

- Published in Food & Flavor

“Strategic Rotting”

Fermentation saved the human diet, argues Krish Ashok, author of Masala Lab: The Science of Indian Cooking. He calls fermentation strategic rotting. The discovery of fire was key to the human’s survival as they learned to cook meat, but fermentation allowed civilization to create bread and alcohol, turn milk into yogurt and preserve a harvest through the winter.

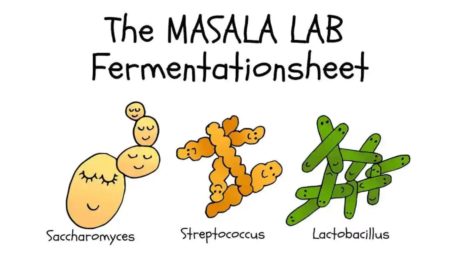

“Fast forward a few millennia, and we have mastered fermentation to the point where we can pick and choose microbes with precision and generate complex flavours in the bargain,” Ashok writes. Pictured, his charming drawings illustrate microbes used in fermentation.

Read more (Mint Lounge)

- Published in Food & Flavor

Syn-SCOBY

Engineers at MIT and the U.S. Army Research Lab have developed what they call Syn-SCOBY, a living material made from laboratory yeast and bacteria. Similar to a kombucha mother, it is a tough cellulose material that researchers say can be used to purify water and detect pollutants. They envision Syn-SCOBY being used in the biomedical field and for food applications.

“We foresee a future where diverse materials could be grown at home or in local production facilities, using biology rather than resource-intensive centralized manufacturing,” said associate professor Timothy Lu, of MIT’s departments of biological engineering and electrical engineering and computer science.

Read more (MIT)

- Published in Science

Q&A: Sophie Burov, Secret Lands Farm

When Sophie and Alexander Burov moved to Toronto, Canada, from Moscow, Russia, in 2007, farming wasn’t on their radar. Both entrepreneurs — she in fashion, he in mining — they were accustomed to life in one of the biggest cities in the world, not to rural farming. And their knowledge of fermented dairy was limited to taste — Alexander loved the tangy kefir he’d been drinking since childhood; Sophie devoured cheese and yogurt.

Sophie was a sheep’s milk aficionado, having tried it years earlier, She had fallen in love with its flavor, but soon learned how hard it was to find fresh sheep’s milk, especially in her native Russia. So when she met a producer at a farmer’s market in Canada, Sophie felt inspired to make her own sheep’s milk products.

“At that moment, I couldn’t even imagine running a farm,” Sophie says. She volunteered at a local dairy and sheep farm, quickly learning that: “Business is business and farming is business too, but it’s love as well. Farming is a lot of love.”

Today, Sophie, Alexander and their son Roman run the 150-acre Secret Lands Farms, south of Owen Sound in Ontario, Canada. Utilizing old-world European farming traditions, they produce a range of artisanal sheep’s milk dairy products at their on-site creamery: kefir, two varieties of yogurt, and 25 cheeses. Their kefir — made from centuries-old Tibetian grains — is also the base for their cheeses. Secret Lands is the only producer in Canada (and one of few in North America) using kefir grains as a culture for cheese.

“Seeing is believing — but tasting is falling in love,” Sophie says. “When you taste our product, you can feel the love.”

Sophie recently spoke with TFA; below are highlights from the interview.

The Fermentation Association: You purchased the farm seven years ago. Farming is hard work! Tell me what made you decide to purchase a farm?

Sophie Burov: Yes, we purchased it in 2013. The idea came about eight years ago. You know sometimes when you reach a point when you need to reconsider the purpose of your life and what you’re doing, why you’re doing it, what’s the purpose of your existing?

The agricultural sector is huge in Canada but not dairy sheep farming , so I started thinking about it as a hobby farm and we’d still live in the city, but it turned in a different direction because if you want just a hobby, it will only be your hobby. If you want something serious, your life and dedication is different when it’s your life. I believe it’s from guidance from God, I was praying a lot.

Looking back, this is the hardest job me and my husband have ever done. But it’s rewarding mentally. I believe in the spirit of the land and the animals and what you’re doing through the product you give to people, you become a bridge connection between the land and the people. Through the product, you can tell much more than through words.

If you want to go farming for money and there’s no love between you and the animals, forget it. There has to be love between you and the animals. Everyday they are teaching us how to be better human beings because sheep are very social. They are also very appreciative animals. They give back their love. If they’re struggling, you’re struggling with them.

We were very, very lucky, because we found the first sheep dairy farmers and breeders in North America — Axel Meister and his wife, Chris Buschbeck [owner of WoolDrift Farm in Markdale, Grey County, Ontario]. They brought this flock from Germany in the middle of the ‘80s and they started developing this flock in the middle of North America. When we decided to do this farm, we met Axel and started going to his farm and volunteering and he was guiding us, telling us what books to read and what to pay attention to with the sheep. His wife Chris is a vet for sheep and she helps us with our sheep.

TFA: How long did it take you to become experts at sheep farming?

SB: We are still learning. The first three years were extremely, extremely difficult. It was a hard time because, working as a volunteer at these different farms, it was very different compared to doing it yourself because all the ups, they’re yours, and all the downs, they’re yours.

TFA: Where do you sell your products?

SB: We sell at the farmers market on Saturday and home delivery twice a week. I believe home delivery is another bridge between the customers and us. If they have questions, we’re always here to answer. It’s not the easiest way to do it, but I believe that for small farmers and small producers, it’s the best way to connect with your customers and make money. We tried to work with retail stores, but retail chains, they are squeezing you. There’s no money for small farms. You can increase your flock, your production, to make more money, but we do not wish to become huge. For now it’s an ideal model for us to sell through online sales to all of the Canadanian provinces

TFA: What is a typical day like at the farm?

SB: Everyday is different. From the beginning, we were working like slaves. It was very unhealthy, all of us were sleeping just an hour, working at the farm then driving to the farmers market. Sometimes our working time was 22 hours a day, it was killing us. But now it’s easier because we have people who can help us in production and my husband Alex has people helping him on the farm, so it’s a little easier. [Secret Lands has anywhere from 8-10 employees, depending on the season].

The most difficult period of the year is lambing season. My husband and son are not sleeping at all. They have naps, but then they’re back to the barn. We do lambing once a year for a few months in spring. We do not do artificial insemination, we do it the way nature intended. The sheep are pasture-raised, grass-fed and no hormones.

TFA: You are Russian natives, where kefir originates from. Did you have kefir before starting the farm?

SB: Yes, kefir started in Russia, it began end of the 19th Century. It came from the Caucasus Mountains. But to be honest, when I started thinking about farming and a sheep dairy farm, I didnt even think about kefir, I was thinking about just yogurt because at that moment I was a yogurt and cheese person. I have hated kefir since I was a kid. My husband has been loving it since he was born.

But when we met our sheep breeder, at that moment he gave me a glass of kefir at his farm. He was just producing kefir for himself, I tried it and thought this was interesting. He gave me a handful of kefir grains, and I made kefir and brought it to our church community for people to try and share with people our idea of what we would be doing on the farm. One lady started asking me so many questions about kefir. And I realized my knowledge about kefir is null. I went back home and started my research and I was just shocked. It was so amazing, it was my ah-ha moment. Kefir is incomparable with yogurt in nutrition. Then my amazement was doubled, tripled, because sheep’s milk kefir, the product is different, the amount of calcium is much higher than cow’s or goat’s milk. In the kefir variation, our body will assimilate twice the calcium and protein.

The real kefir — made from kefir grains — it’s very limited on the market because it’s difficult to make. Seven years ago I had a handful of kefir grains, but now I can produce nine pails of 15 liters each of kefir at the same time. It’s not a huge amount actually if we compare it to someone who does it commercially. It’s impossible to make money with that amount of product. When people ask why our product is high priced, I tell them because it’s the real stuff.

TFA: Tell me some of the benefits of sheep’s milk kefir.

SB: It’s a natural probiotic, it’s the most natural probiotic in the whole world. Some scientists are saying it has 50 different variations of probiotics.

If you are taking pills or taking kefir from commercial cultures, you are not digesting the good bacteria. But if you take the real kefir, it’s becoming you and it works. People ask “Why am I supposed to drink it all the time? What’s the reason?” I tell them even the best troops in the whole world can do a lot, but if you are not feeding them, they become weak. These troops are fighting the bacteria in your body and they’re fighting nonstop, invisibly fighting bad bacteria in your body. People need to understand there’s no miracle. You can’t drink a glass or a liter and that’s all. You need to do it constantly and it will give you the health benefits from the nutrients and vitamins. I drink half a glass for my breakfast and and half a glass at night.

In kefir, your body assimilates the nutrients and vitamins. Sheep’s milk is easier to digest because it’s closest to mother’s milk, more than goat or cow milk — it’s a superior milk. You can even freeze this milk, we freeze it for the winter time and when you defrost it, it doesnt change the structure. The globule of the fat in sheeps milk is four times smaller than cow’s milk. It’s easiest to digest for people, especially with lactose issues. Same with our cheese made from kefir, it has the same benefits.

TFA: What about your other fermented products? Tell me about the baked milk yogurt.

SB: The baked milk yogurt can be confusing to people because they say “Doesn’t it kill all the probiotics in your yogurt?” No, we are slow cooking it, and then we add cultures. It is Russian and Ukrainian, this process of making yogurt. It goes back to history when people in villages were baking bread in a wooden oven. It was always pre-heated, they would put milk in a cast iron pot or clay pot. It would stay there overnight, and the water is evaporating and the milk sugar is caramelizing. We call it the healthiest creme brulee. It has the taste of caramel, but no sugar or caramel added because of the process of the caramelization of the lactose.

TFA: You make traditional yogurt, too?

SB: Yes, we are working with cultures from Italy. I tried to work with what’s available here, but it gave me a really sour, tart taste. It was too genetically modified, and that genetically modified culture is not allowed in Europe. We’re bringing all our cultures for our yogurt from Europe.

TFA: Tell me more about your cheeses.

SB: We do different varieties of cheeses called kefir cheese, we use zero commercial cultures. We are using only kefir. It takes more time, it changes a little bit of the taste for the cheese, but it’s the same culture. We’re able to produce fresh cheese to a few-years-old Pecorino. But it’s the same culture.

David Archer, he wrote The Art of the Natural Cheesemaker, I met him just before we started making kefir cheese. At that moment, his book had just released and people introduced us at the farmers market. He came to our farm and we spent a month together in our small-size commercial kitchen and creamery and he helped convert everything to kefir cheeses.

I’m always asking people just think about the history of the cheesemaking, cheesemakers they didn’t use the cultures from the lab, it was a natural fermentation. It was the same farm with the same bacteria, they’ve been doing different varieties of cheese, but it depends on your region because the environment is different. Sometimes, you don’t know what’s involved because the weather is different, the humidity is different and even our mood is different. If you’re not in a good mood, it comes out in the cheese.

Same with kefir cheese, we’re using the same kefir as a culture for our milk, and it gives us different results. Even with our soft-ripened cheeses, Camembert and Brie, the rind we are growing, it does not have any artificial bacteria that people put on top of the cheese to grow a rind. Kefir gives this ability to grow the rind naturally. But you need to be thoughtful and it involves a lot of labor because you need to keep your eye on the cheese everyday to see what’s growing on top. And you need to develop the right bacteria for the rind of the cheese.

TFA: Is the process to make a kefir cheese different from a traditional cheese?

SB: A little bit, but now much. The process to make it takes more time than traditional cheesemaking because you need to add kefir and wait. But it’s worth it because it’s a superior food that brings you all the good protein. It’s easier to digest compared to even meat because it’s naturally fermented.

TFA: How long did it take you to perfect these recipes?

SB: It’s an ongoing process. From the beginning I didn’t plan to do 25 cheeses. But I was surprised, people started asking me at the farmers market if I would make hard cheese. Now Pecorino is our top seller and our main product, it’s a sheep’s milk cheese made of full-fat, whole sheep’s milk.

Sometimes people are suspicious — “Oh a Russian, doing Pecorino in Canada?” But when they taste it, they love it.

Even as small producers, we are like big producers, because we are doing a big range of products. We have four more cheeses planned for the future. The sheep’s milk gouda is in the aging room now.

TFA: How does the taste of a fermented sheep’s milk product taste compared to fermented goat or cow dairy?

SB: Sheep’s milk is very sweet and high in fat, but good fat. It’s very smooth and creamy. My first impression when I tried a glass of sheep’s milk, it was like I was drinking the best cow’s cream of my life. It’s rich, but not heavy because the globule of the fat is very small. It gives richness, but at the same time, lightness. It’s so full of the different nodes of the taste. It’s sweet but not overly sweet, it’s balanced. The quality of the milk affects all the range of the products that we do.

Sheep milk is a very good balance between rich and light.This taste goes through the product. It’s totally different from goat milk, it doesn’t have a strong taste. Many people don’t like the taste of goat milk, the smell and taste. Sheep doesn’t have that strong taste at all.

TFA: I love that you are very invested in the welfare of your animals.

SB: For me the most important, I care how people are treating the animals. If the animals are healthy, free-range, pasture-raised, people are taking good care of them, they’re not giving them chemical-produced silo. We’re giving our animals fermented hay because it’s easier to digest. Year-round, our animals are grass-fed. We are not just farmstead producers, we are much more. Our main concern is the health of our soil. The quality of the product, the health of the product, it starts from the health of our lamb. Only good soil can guarantee good health for your animals.

TFA: Where do you see the future of fermented products?

SB: I believe in the future of fermentation. However, it’s not easy. For example, back in Russia, back in Europe, my family we’ve been doing sauerkraut since I can remember. Even here in Canada, living in downtown Toronto, even when we were in a condo, I was making sauerkraut. And kombucha.

But people are losing that connection to their food. They need the right guidance to reconsider their eating habits. I believe it will take some time to change, but we are optimistic.

- Published in Business, Food & Flavor

A Yeast Primer

Brewers, winemakers and cidermakers are continually on the hunt for the ideal flavor profiles for their fermented beverages. And the key to manipulating those flavors is yeast.

“With beer, you’re taking this kind of gross, bitter soup of sweet barley and hops, and the yeast makes it taste good. Depending on the yeast that gets put in it, it can make it taste like 400 different things, so there’s so much potential there. I think that’s really exciting,” says Richard Preiss of Escarpment Laboratories. Priess was joined by Doug Checknita from Blind Enthusiasm Brewing and Patrick Rue from Erosion Wine Co. to discuss the world of yeast in TFA webinar, A Yeast Primer.

“If you’re invested in vegetable fermentation, yeast might be sort of clouded in mystery and something that is unwanted,” says Matt Hately, TFA advisory board member who moderated the webinar. “It’s what you live by in beverage fermentation in wine and beer and it’s the key to unlocking flavors to make that magic happen.”

Domesticated vs. Wild Yeasts

Just as dogs and cats were domesticated by humans, yeasts have been as well, says Priess, whose company makes and banks yeasts. They are microscopic organisms that adapt, “so if someone’s making beer for over the span of hundreds or thousands of years then the yeast is going to change to kind of get better at fermenting that beer and maybe it’s not going to be so good at surviving out in the wild, just like our toy poodle versus our wolf.”

Other fermented drinks, like wine, sake and cider, use different yeasts with their own specific sets of traits. This is why a wine yeast can’t be used in a beer and vice versa, “though there are some opportunities to experiment.”

Fermenting with wild yeasts has become increasingly in vogue with beer brewers. Aspirational brewers are finding yeasts on the skin of fruit or the bark of trees.

The panelists on the webinar praise experimentation, but note there is risk. Priess says yeasts designed to survive in the wild can be challenging to use in a beer. Checknita points out the safety factor in using yeasts directly from nature as well, “you can get stuff that’s harmful to human health so you have to be careful with your pH levels and what controls there are.”

Traditional winemakers, on the other hand, have long used the wild yeast on grapes to ferment. Rue notes that 10 years ago winemakers began to deviate from this tradition to use pure cultures instead. This process is how many large-scale, industrial producers operate today. But smaller winemakers, who often want to emphasize the specific traits of their terroir, generally use native yeasts and traditional winemaking techniques.

“It’s amazing how wine is how God intended wine to be made because you let nature happen and you’ll probably have a pretty good result with natural fermentation,” Rue continues, “where beer, it’s very touch-and-go, you have to have the perfect conditions and I’ve been able to do spontaneous fermentation with those yeasts.”

The Yeast Family Tree

There’s a large and continually-growing family tree of yeasts, with branches forming for genetic diversity and specialization.

Priess sees three new trends emerging in yeasts: traditional yeasts (like Norwegian kveik) being rediscovered, yeast hybridization (similar to cross-breeding a tomato) and genetic engineering to enhance certain traits of yeast.

“That’s the exciting part of what we’re doing is no one really knows the best approaches to using beer yeast yet, but there’s a lot more new science that’s happening, a lot more brewers that are experimenting, and together we’re collaborating to understand how to work with yeast better and kind of unlock new flavors and new possibilities,” Priess says.

Checknita agrees. He says new yeasts are forming new family trees through spontaneous fermentation, which is taking the base of a beer and experimenting to “push and change those yeasts to do what we want and get that clean flavor that’ll make a beer that tastes good to the human palate.”

- Published in Food & Flavor

Reducing Wine’s Alcohol Content

Can you make wine with lower alcohol content? Researchers at Washington State University think so. They are growing wild in a lab to study how the yeasts behave and affect flavor and alcohol levels.

Yeasts used in winemaking — typically Saccharomyces — ferment by consuming the sugars in grapes, producing alcohol. If the grapes have higher sugar levels, they may produce wine with a higher alcohol percentage. But higher alcohol can have a range of negative consequences — bitter taste, incomplete fermentation leaving residual sugar and even higher taxes for the winemaker. WSU researchers hope, by perfecting wild non-Saccharomyces yeast strains, they can help the state’s winemakers better control the fermentation process, and reap the benefits of lower alcohol percentages.

Read more (Daily Evergreen)

- Published in Food & Flavor, Science

Pairing Sake with Food

Does sake go well with Western dishes? Josh Dorcak, chef of Japanese restaurant Mäs, tells Forbes why he thinks sake is an excellent pairing with all food types, maybe even more so than wine.

“Sake pairs with everything,” Dorcak says. “With wine often it seems like there are these rules that one must follow while sake often fits the bill for creative pairings.”

Read more (Forbes)

- Published in Food & Flavor

Egypt’s 5,000-year-old Brewery

Archaeologists from NYU and Princeton have uncovered the world’s oldest industrial-sized brewery. Located in southern Egypt near the Abydos ruins, the facility dates from 3000 B.C. Many of Egypt’s early kings were born in Abydos, so it’s assumed the brewery made ceremonial beer for ritual offerings and royal funerals.

“The fundamental significance of the Abydos brewery is its scale relative to anything else in early Egypt,” project co-leader Dr. Matthew Adams said. The brewery likely produced about 22,400 liters with each batch (possibly weekly.) “That is a huge amount of beer by any standard, even in modern terms. It’s absolutely unique.”

Read more (Wine Spectator)

- Published in Science