Mexican Hard Cider

An Oregon cidery is taking an interesting approach to hard cider, ciders inspired by aguas frescas.

La Familia Cider Company founder José Gonzales is a first-generation Mexican-American. He runs La Familia Cider Company with his wife, Shani, and their kids Jay Jay and Jezzelle. José and Shani grew up drinking aguas frescas, but couldn’t find those drinks in Oregon.

“As my wife and I were enjoying Oregon craft beer and cider, she said, ‘Too bad there aren’t any of the flavors we grew up with,” José said. So they developed their own brand with flavors reflecting their heritage.

Their ciders are from freshly-picked, northwest-grown apples, but the flavors reflect the family’s Mexican heritage. Mainstay flavors include Manzana, Tamarindo and Hibiscus.

“With our ciders we wanted to do something a little bit different,” explained Jay Jay. “Change up the game a little bit.”

Today, the Salem, Ore.-based brand is in more than 50 stores in Oregon and Washington.

Read more (KGW8)

- Published in Business, Food & Flavor

Brewing Boom in Chicago

Dubbed the craft beer capital of America, Chicago has a brewery scene that is innovative and diverse. Numerous breweries have opened over the last decade, with now about 160 breweries across the city and surrounding suburbs. Ferment Magazine says Chicago’s craft brew industry is “one of the most expressive and most exciting experiences anywhere in the world, let alone in the U.S.”

“We have a very strong culinary scene in Chicago and a lot of consumers that have an open mind. There’s a lot we could throw at the market and people are very accepting of the different brewing styles, both old world and new world,” says Tyler Davis, founder and director of fermentation at Duneyrr Artisan Fermenta Project. “Of all the [different beer styles] we could produce, there are brewers in Chicagoland that specialize in that.”

Chicago’s Brewers

Duneyrr (pictured) focuses on co-fermentation. Using craft beer as a base, Davis makes fermented drinks with ingredients from wine, cider and mead.

“It all came from me reaching the end of my creativity in a brewery. I got tired of creating the same format,” says Davis, who worked in Chicago as head brewer at Lagunitas and at Revolution Brewing. He began experimenting with co-fermentation and found “how you ferment wine is shockingly similar to beer. There are nuances of both, but I enjoy blurring the lines.”

The Nordic-inspired drinks he produces include his favorite, Freya Franc,(a sour hybrid with passion fruit and Sauvignon Blanc grape must. Duneyrr also has a Moderne Dune line, a sister brand that specializes in modern ingredients and techniques.

Davis studied at the Chicago-based Siebel Institute of Technology, the oldest brewing school in the U.S. and alma mater to many area brewers. One alum is Dave Bleitner, who founded Off Color Brewing with his Siebel classmate, John Laffler. The two focus on funky fermentation.

“Even with our first flagship gose, Troublesome, we have always been fermentation-focused. Even when we are dumping in a bunch of rooibos tea and pumpkin pie spices into a beer, we believe beer needs a proper fermentation to work,” Bleitner says. “Maximizing flavor from yeast is always going to result in a superior beer. But beyond our focus on fermentation, we are not afraid to dump a bunch of rooibos tea and pumpkin pie spices into a beer. So the dual concepts of focusing on the basics of fermentation while teetering on the border of innovative and insane is something no one else should or can replicate.”

When Off Color launched in 2013, Bleitner and Laffler didn’t want to go the mainstream craft beer route. “We had some crazy idea that craft beer consumers wanted variety from their beer,” Bleitner said. They didn’t follow the usual craft beer formula of launching with an IPA. They started with lesser-known styles like gose and kottbusser. He notes “we really hit our stride with Apex Predator Farmhouse Ale.”

At 15 years old, Half Acre Beer is one of Chicago’s pioneers of the craft beer scene. The brewery is the third-largest independent brewer in Illinois and now distributes their beer all over the country. They run a brewery and taproom in Chicago. Their best seller is Daisy Cutter pale ale, but they also sell seasonal and monthly varieties.

“These days we’re kind of the older, bigger brewery among the smaller, newer breweries. We focus on hop-forward and traditional beers,” said Gabriel Magliaro, president of Half Acre. He echoed the sentiment expressed by Duneyyr and Off Color – Chicago brewers are a supportive community. “Today I think we can call Chicago a beer town and, no matter how you choose to define that, we show up well.”

The Next Beer Buzz

Craft beer brewers see increasing competition from the better-for-you, healthier fermented drinks, like kombucha, seltzer and low- or non-alcoholic beverages.

Duneyrr is starting to specialize in lower-alcohol fermented brews. Off Color, too, has added a lower-alcohol beer, a 2.5% ABV Belgian-style they call Beer for Lightweights.

Lagers are making a comeback as well. “A lot of old world brewing styles, there’s become a renaissance,” Davis says. He sees “candy beers” – filled with artificial flavors – going away. Bleitner, too, is not a fan – he calls hard seltzers “fermented pixie sticks”. But he’s found that consumers like flavor in their brews. When sales of Off Color’s Troublesome gose began to decline, adding lime juice revived the drink. They called it Beer for Tacos and “it took off almost immediately.”

In an era fraught with pandemic shutdowns, retail inflation and supply chain issues, brewers foresee challenges ahead.

“Obviously the pandemic has been a factor, one that is still playing out,” Magliaro says. “The on-premise was rocked and I don’t think anyone knows how that will look in five years.”

Climate change is affecting grain crops, “things we knew to be stable are now being highly influenced by the weather patterns,” Davis says. The hot weather is changing the nutrient level of grains, leading to grains higher in protein. “It’s pretty scary,” he says.

But beer will always find a way to thrive.

“We make something embedded in human culture,” Magliaro says. “Beer is a gathering liquid that has place almost anywhere for almost any occasion with so much heritage to its being. The industry, consumer landscape and world can do what it needs, but beer will live on.”

- Published in Business, Food & Flavor

Ukraine Cidery Destroyed by Russia

Berryland, an award-winning Ukranian cider and mead producer, was destroyed by a bomb in a Russian air raid. The employees escaped and were uninjured.

Owner and oenologist Vitalli Karvyha built his facility six years ago in the Makariv District of Kyiv. Karvyha makes his ciders and meads from local fruits and berries, and raised bees on site for the honey for his mead. His fermented beverages have earned him awards at Vintage Cider World in Germany and the Mazer Cup in Colorado.

Karvyha says he plans to rebuild, updating his status through Berryland Cidery’s Facebook page.

Read more (Broken Palate)

- Published in Business

Tastier Apple Spirits

Thanks to their high sugar content and strong flavor, apples have been a great base for spirits like cider, calvados and applejack for hundreds of years. But “many decisions about their processing are still subjectively determined.” When to stop distillation for the most flavorful liquor, for example, is open to question. But new research has identified the best conditions for making apple-based spirits with the most desirable qualities and taste.

Researchers with the American Chemical Society fermented apples into a mash, then distilled it in a German-style batch column. Heat concentrates the alcohol and “removes unpleasant fermentation byproducts, such as carboxylic acids that can impart unclean, rancid, cheesy and sweaty flavors.” The researcher’s mash was continuously monitored during heating, and the levels of the nine carboxylic acids measured.

Heating the mash too quickly yielded unwanted flavor compounds and a bland aroma. But raising the temperature of the cooling tower slightly produced a good fragrance intensity, and reduced carboxylic acid levels.

Read more (American Chemical Society)

- Published in Food & Flavor, Science

Food and Beverage Laws Passed in 2021, Part 2

Changes in the global food system influenced the types of laws U.S. legislators passed in 2021. States are loosening the regulations on breweries and wineries, offering more government support to local restaurants, allowing the sale of homemade foods and cracking down on hidden fees from third-party food delivery services.

In our last newsletter, we shared the food and beverage laws passed in 20 states in 2021. The list below completes the balance of the country — Massachusetts to Wyoming.

Massachusetts

HB21 — Allows temporary licenses for nonprofit charitable corporations. Allows alcoholic beverages sold to be donated at no charge to the license holder.

HD1331 — Provides that a license to operate a restaurant may be connected to other on-site premises, even if it is not a grocery store.

SB2475 — Extends to-go cocktail sales through May 1, 2022.

SB2603 — Sets minimum standards for the confinement of chickens, veal calves and pigs, and bans the in-state sale of products that don’t comply. Mandates cage-free conditions for egg-laying hens with welfare enrichments like perches, dust bathing areas, scratching areas and next boxes. The law also expands coverage to egg products and liquid eggs.

SB2841 — Reform state’s franchise laws, allowing a new qualified brewer for craft brewers. Allows craft brewers who produce fewer than 250,000 barrels annually to end their contract with a wholesaler. It repeals the state’s 1971 franchise law, enacted to protect in-state distributors from larger, out-of-state, foreign brewers, during a time when the craft beer industry did not exist.

Michigan

HB4711 — Allows baseball stadiums at Michigan universities to serve alcohol.

SB49 — Allows wineries, breweries and distilleries to operate both an on-premise and off-premise tasting room at the same location.

SB141 — Allows small craft distillers to self-distribute up to 3,000 gallons per year of product to retailers. Also allows craft distillers to ship directly to consumers.

SB142 — Allows a small wine maker to self-distribute directly to retailers.

SB144 — Expands the definition of a mixed spirit drink to allow increased ABV percentage.

SB559 — Amends state liquor code to allow more entertainment complexes to receive liquor licenses; drops number of needed races from seven to two for a motorsports venue to qualify for a liquor license.

Minnesota

SB958 — Raises the sales cap for cottage food sales from $18,000 (formerly the lowest sales cap in the country) to $78,000.

Mississippi

HB562 — Allows online sales of cottage foods.

HB572 — Expands boundaries of resort areas where alcohol can be sold.

HB997 — Authorizes private retailers to obtain wholesaler permits for alcohol sales. Also removes the state’s Department of Revenue as a wholesale distributor of alcohol.

HB1091 — Amends code to increase the alcohol content for alcoholic products. Defines how much product can be produced and sold at a microbrewery.

HB1135 — Allows alcohol delivery from a licensed delivery.

HB1288 — Amends code to allow a charter ship to sell and serve alcohol.

Missouri

HB537 — Allows online sales of cottage foods and removes the $50,000 sales limit on cottage foods.

HB574 — Prohibits inspectors of agricultural grounds or facilities to enforce laws of states other than MIssouri.

SB126 — Legalizes the permanent sales of to-go alcohol. Also expands the sale of alcohol in the state on Sundays.

Montana

HB79 — Provides regulatory clarity for how breweries produce fermented-style beverages, including any alcoholic beverages made by fermentation of malt substitutes, like rice, grain, glucose, sugar or molasses.

HB157 — Removes restrictions for alcohol licensing, allowing brewers and immediate families to both hold a license.

HB226 — Makes permanent the curbside delivery and to-go drink options for licensed retailers established during the Covid-19.

SB199 — Establishes the Montana Local Food Choice Act. The food freedom bill exempts certain homemade or cottage food products from food licensing and inspection regulations. It also expands the types of foods that can be sold.

SB247 — Allows colleges and universities in the state to serve beer and wine at sporting events.

SB320 — Legalizes the home delivery of beer and wine.

Nebraska

LB274 — Amends the Nebraska Liquor Control Act, making permanent licenses to sell to-go alcoholic beverages. Also allows craft breweries and wineries to sell alcoholic beverages at open-air farmers markets.

LB324 — Establishes the Independent Processor Assistance Program, improvising the Nebraska Meat and Poultry Inspection Law. Helps small locker plants make the transition to a federally-inspected facility.

LB396 — Adopts the Nebraska Farm-to-School Program Act, which establishes a structure to facilitate communication between farmers and schools.

Nevada

SB297 — Requires the Council on Food Security to research and develop recommendations on community gardens and urban farms.

SB307 — Prohibits direct-to-consumer (DTC) shipping of alcohol from both in-state and out-of-state breweries, distilleries and retailers. In-state retailers can also make local deliveries from licensed wholesalers. However, DTC wine shipments will still be allowed.

SB320 — Requires food delivery services such as Uber Eats and DoorDash to disclose fees to consumers, breaking down what price is for food, taxes, delivery fee and commission charted to the restaurant. Restaurant committees are limited to 20% of a credit card processing fee during a state of emergency (like the Covid-19 pandemic).

New Hampshire

HB226 — Gives state department of agriculture authority to stop the sale of any produce in violation of state agricultural laws.

HB345 — Establishes a license for wild mushroom harvesters. Allows state department of health and human services to fine people who distribute wild mushrooms without a license.

HB593 — Requires food delivery service to enter into an agreement with a food service establishment before offering delivery service from that restaurant.

SB66 — Allows takeout and delivery of alcoholic beverages.

SB125 — Eases certain regulatory restrictions for a number of beverage manufacturer licenses. Removes limitation on quantity of beer a beverage manufacturer may sell in a day to the public and allows direct-to-consumer shipping to consumers within the state.

SB155 — Allows restaurants to permanently expand dining into a shared space, like a sidewalk or street, with approval from local authorities. This temporary dining space was originally established during the Covid-19 pandemic.

New Jersey

AB1091 — Requires Division of Travel and Tourism to advertise and promote tours of breweries in the State.

AB1478 — Permits theaters with 50 seats or more to apply for liquor license.

AB5906 — Rescinds prohibition on return of certain items purchased from retail food stores during Covid-19 state of emergency. It also provides that future limitations on returns occur during declared public health emergencies.

SB673 — Establishes New Jersey’s first cottage food law (they were the only state in the U.S. without a cottage food law). Allows home-based producers to make food from home rather than a commercial kitchen. These producers must obtain a license every two years, cannot earn more than $50,000 a year and are limited by products that can be sold (though state permission can be granted for additional items).

SB3340 — Expands opportunities for restaurants, bars, distilleries and breweries to operate during the Covid-19 pandemic. Provides outdoor dining space and opens new permits for sales at farmers markets.

SB3364 — Allows certain liquor licenses to acquire alcoholic beverage licenses from a retail food store that is a bankrupt asset.

New Mexico

HM1 — Requests the New Mexico Department of Agriculture to study the economic benefits of regional mobile livestock slaughter units, which would make livestock slaughtering easier for small ranchers.

HB177 — Enacting the Homemade Food Act. Allows anyone in the state to start a cottage food business — and opens sales to be from home and online (cottage food sales were previously limited to events only).

HB255 — Allows restaurants to purchase a liquor license at a more affordable rate ($2,500-$10,000, depending on size) if serving alcohol with dinner. Also allows alcohol deliveries with food.

HB303 — Bans unlawful liquor incentives. No liquor licensee shall accept money or a gift of monetary value to influence the purchase or a certain brand of alcoholic beverage.

SB1 — Allows qualified state food and beverage establishments to claim a temporary gross receipts tax (GRT) deduction on sales of food and beverages from March 2, 2021 through July 1, 2021 as a stimulus incentive.

SB2 — Waives the annual liquor license fees for licensees, aiming to boost businesses hit by the Covid-19 pandemic.

New York

AB952 — Directs the commissioner of agriculture and markets and the commissioner of economic development to work with the state’s land grant university system to produce a report to provide advice, guidance and recommendations on improving the resiliency of the state’s farm and food supply. Also will provide guidance on the related supply chain logistics to address food shortages, food waste and the inability to get New York farm goods to markets that occurred as a result of the Covid-19 pandemic, with the goal of creating permanent solutions beyond the state of emergency to reflect the changing wholesale, retail and consumer marketplace.

AB4613 — Creates a task force on improving urban and rural access to locally produced, healthy foods.

AB5386 — Establishes the New York Soil Health and Climate Resiliency Act to enhance and maintain the health and resilience of agricultural soils. The program will assist farmers in improving the health of their soil. It also establishes a climate resilient farming initiative to promote and encourage farmers to reduce the effects of farming on climate change and to adapt to and mitigate the impact of climate change by improving and maintaining water management systems and soil health.

AB7506 — Requires grease traps at food service establishments be designed to withstand expected loads and prevent unauthorized access, making them safer for the general public.

AB7207 — Authorizes and directs the commissioner of agriculture and markets to conduct a study on urban agriculture, including vertical farming, community gardens and urban farming.

SB1630 — Requires third-party food delivery services to have a valid agreement with a merchant before they advertise, promote or sell the merchant’s products on their platform.

SB2743 — Authorizes the issuance of a temporary retail permit by the state liquor authority to licensees located in a municipality having a population of one million or more persons.

SB6353 — Allows restaurants to utilize municipal spaces like sidewalks and streets for outdoor dining for another year. First granted under an executive order during the Covid-19 pandemic, the law makes restaurant use of public spaces to allow restaurants to recover from the pandemic.

North Carolina

HB4 — Extends ABC permit renewal payment deadlines for bars.

HB890 — Allows consumers to order online and pick-up alcohol from state Alcoholic Beverage Control stores, expands growler sizes from 2 to 4 liters, loosens rules for distillery tours and allows distillers to sell alcohol at festivals.

North Dakota

HB1284 — Modifies special event alcohol permit requirements to remove the rule that persons under 21 years of age must remain out of the area where alcohol is served.

HB1475 — Creates a $10 million agriculture diversification and development fund to provide loans and grants for value-added agriculture businesses in the state.

SB2220 — Moves the sale of Sunday alcohol sales to 8 a.m., the same as the rest of the days of the week in the state..

SB2321 — Allows microberies and taprooms to ship products in-state.

Ohio

HB665 — Increases the amount a county or independent agricultural society receives for operating expenses from a county. Removes caps on junior club membership .

HB669 — Makes to-go alcohol sales permanent.

HB674 — Allows home delivery of alcohol, as long as the beverage is served in an original container.

SB102 — Sweeping liquor reform. Lowers the age for serving alcohol to 18, expands Designated Outdoor Drinking Areas spaces, clarifies that homebrewers are allowed to brew their own drinks, enter them in tasting competitions and share them at local club gatherings.

Oklahoma

HB1032 — Creates the Homemade Food Freedom Act which provides for regulation and oversight for the production, transportation and sale of homemade food products. Now allows almost all types of baked, non-perishable and perishable foods. Also increases sale limits from $20,000 to $75,000, allows direct sales and allows shipment of non-perishable items.

HB2117 — Allows certain communication and interaction via social media by alcohol wholesalers, beer distributors and retailers.

HB2122 — Allows the sale of to-go cocktails, mixed drinks or single-serve wine in a sealed container for off-premise consumption.

HB2277 — Permits licensed alcohol retailers to offer different drink specials at various locations owned and operated under their license, like a happy hour.

HB2380 — Allows customers to self-pour their own beer, wine or mixed beverage from automated machines.

HB2726 — Allows Oklahoma small businesses to offer bottle service to their customers.

SB85 — Authorizes holders of multiple small brewer licenses to sell beer at multiple locations.

SB262 — Requires wine and spirit wholesalers to remit alcohol excise taxes when purchasing alcoholic beverages for sale within the state except for wine shipped by wineries possessing a Winemaker Self-Distribution License.

SB315 — Allows licensed distillers to sell spirits for on- or off-premise consumption on distillery property or in an area connected and controlled by the licensee.

SB385 — Allows retail spirits, wine and beer licensees to host alcoholic beverage tastings.

SB499 — Requires that customer receipts for alcoholic beverages purchased at catered, public and special events include a line item for the 13.5% tax collected.

SB760 — Allows multiple alcohol licensees to designate a common drinking area.

Oregon

HB2111 — Changes name of “Oregon Liquor Control Commission” to “Oregon Liquor and Cannabis Commission.”

HB2264 — Alcohol reform bill. Allows Indian tribe or airline that holds full on-premises sales license to negotiate with Oregon Liquor Control Commission purchase price of distilled liquor for specified sales. Directs Oregon Liquor Control Commission to study alcohol. Changes definition of “malt beverage.” Allows nonprofit organizations to sell alcoholic beverages for up to 45 calendar days per year without license issued by commission. Allows holder of full on-premises sales license to sell, deliver and ship to consumers specified alcoholic beverages for off-premises consumption. Allows holder of limited on-premises sales license to deliver and ship to consumers specific alcoholic beverages for off-premises consumption. Allows holder of off-premises sales license to sell specified alcoholic beverages for off-premises consumption. Allows holder of temporary sales license to ship specified alcoholic beverages to consumer. Repeals license application fee. Allows advertising by liquor store to be visible from outside store. Specifies that retail sales or distillery outlet agent’s deposit with commission is of check and cash receipts. Specifies wine containing more than 16% alcohol by volume is taxed at 10 cents per gallon. Requires manufacturer, purchaser and distributor of alcohol to retain records for three years.

HB2742 — Allows holder of off-premises sales license to sell factory-sealed containers of malt beverages that hold more than seven gallons.

HB2363 — Allows certain holders of temporary event licenses to sell specified alcoholic beverages for on and off-premises consumption at more than one location on licensed premises — or have up to three premises licensed under single temporary sales license and operate for up to 30 day.

HB2395 — Modifies single-use checkout bag prohibition in the state. Changes definition of “recycled paper checkout bag” to include bags that contain non wood renewable fiber.

HB2611 — Permits agricultural building to be used for uses other than uses set forth in definition of “agricultural building” if additional uses are incidental and accessory to defined uses, are personal to farm owner and farm owner’s immediate family or household and do not pose hazard.

HB3361 — Requires third-party food platform to enter into agreement with restaurant before arranging delivery of orders from food place or listing food place on application or website. Requires third-party food platform delivery service to receive written consent from restaurant before arranging for delivery or order from restaurant.

SB806 — Includes “fortified cider” in definition of cider. Allows holder of direct shipper permit to ship up to five cases of wine per month to Oregon residents. Deletes requirement that commission charge application fee for new licenses. Provides that the alcohol commission may allow applicant to defer or waive payment of annual license fee if Governor declares state of emergency.

Pennsylvania

HB425 — Allows a liquor licensee that has closed either permanently or for a long time to sell its liquor license.

HB427 — Gives establishments with liquor licenses a 15% discount (instead of 10%) on the purchase of liquor from the state stores for three years.

SB434 — Alters “sell by” and “best by” dates on milk. Allows processors to apply for Department of Agriculture approval to exceed the current 17 day limit.

Rhode Island

HB5131 — Prohibits a food service establishment from providing a consumer with a single-use plastic straw, unless the consumer requests such a straw.

HB5214 — Eliminates the $10.00 fee requirement for businesses to obtain a sales tax permit.

HB5758 — Establishes the state’s first Cottage Food Law, but only allows farmers to sell homemade products.

SB142 — Allows the sale of alcoholic beverages on New Year’s Day by retail Class A licensees.

SB364 — Entitles dairy farms to the exemptions from taxation already granted to farmland, forestland and open space.

SB555 — Authorizes a Class B liquor license holder to sell to-go alcoholic beverages with take-out food orders (but rule will sunset on March 1, 2022).

SB788 — Prevents third-party food delivery services from using the likeness, registered trademark or any intellectual property belonging to the restaurant to falsely suggest sponsorship or endorsement without the restaurant’s consent.

South Carolina

SB619 — Allows more off-site tasting rooms in the state. Amends 1976 law affecting distilleries, breweries and wineries, to establish off-site “satellite locations” for sale of their products.

South Dakota

HB1109 — Updates state homebrew legislation to include cider as a permissible homemade alcoholic beverage. Allows (in limited quantities) for homemade alcoholic beverages permissible to be sold on licensed premises for certain events, and allows homebrewers to transport homemade alcoholic beverages from their household.

HB1121 — Deregulates the homemade or cottage food market. Repeals requirement that homemade canned goods must be inspected by a third-party authority for pH levels. Replaces lengthy warning that food wasn’t produced in a commercial kitchen and required allergen listing with a shorter summary. Allows sellers to sell their products through third parties without getting a good service license (as long as they aren’t making more than $150,000 a year).

HB1153 — Authorize the Board of Regents to contract for the design and construction of a new dairy research and extension farm on the campus of South Dakota State University, with equipment and furnishings.

Tennessee

HB306 — Extends the Tennessee dairy promotion committee to June 30, 2029.

HB1129 — Adds requirements for farmers to participate in herdshare programs, like maintain owner records, include warning labels on products and notify owners in case of contamination.

HB1514 — Reduces the population threshold (from 925 to 700) to make a municipality eligible to hold a referendum on the sale of alcoholic beverages.

SB17 — Allow breweries to self-distribute 1,800 barrels of beer throughout the state each year without having to go through a wholesaler.

SB269 — Authorizes a delivery service licensee to charge a fee based on a percentage of the sales of the alcoholic beverages or beer being delivered; limits the fee to no more than 10% of the price of each alcoholic beverage sold.

SB299 — Defines “food hall” for purposes of consumption of alcohol on the premises of a food hall; enacts certain requirements governing the operation of a food hall.

SB403 — Requires state to disclose certain information on contracts with wholesalers of alcoholic beverages.

SB591 — Authorizes a person or entity holding liquor license to sell or transfer their alcoholic beverage inventory to another licensee if they’re closing their establishment.

SB681 — Allows to-go alcohol sales for the next two years.

SB705 — Prohibits licensure as a winery direct shipper of in-state or out-of-state wine fulfillment houses.

Texas

HB1024 — Allows permanent sales of to-go beer, wine and mixed drinks for pickup and delivery food orders.

HB1276 — Allows restaurants to sell bulk foods directly to the public.

HB1518 — Loosens alcohol restrictions on Sunday mornings, allowing sales starting at 10 a.m. rather than noon.

HB1755 — Allows customers to take home unopened bottles of wine.

HB1957 — Sets new standards on what can be labeled as a Texas wine. If putting Texas on the wine label, winery must grow majority of grapes (75%-95%) within the state, county and/or vineyard on the label.

HR2002 — Recognizing June 2022 as National Dairy Month in Texas.

SB617 — Allows all food producers to sell food directly to consumers, not just farmers. Limits permit fees.

SB911 — Bans third-party food delivery service from using a restaurant’s trademark or charging a restaurant fees (unless agreed upon in writing). Also protects a restaurant from predatory food delivery services — allows a restaurant to be removed from the third-party delivery services listing if requested, and required third-party delivery services to provide consumers with a means to express concerns with their delivery. Gives restaurants the power to sue a third-party delivery service if it violates the terms. Also prohibits cities and counties from creating interfering regulations than what the state approved.

SB1226 — Allows brewpubs to legally host tastings.

Utah

HB94 — Legalizes microenterprise home kitchens, allowing home chefs to sell their homemade meals.

HB296 — Creates the Utah Soil Health Program.

SB137 — Gives the Utah Department of Alcoholic Beverage Control an additional $4.3 million to raise salaries for its retail clerks, warehouse workers, store managers and assistant managers up to market standards.

SB147 — Prohibits farm owners and operators in the state from confining egg-laying hens to enclosures. Must implement cage-free housing systems by 2025.

HB166 — Criminalizes theft of livestock.

Vermont

HB218 — Expands raw milk sales for producers selling at farm stands and CSA’s in the states.

HB313 — Extends for two years the governor’s executive order to allow curbside pickup and delivery of alcohol.

HB434 — Establishes the Agricultural Innovation Board.

SB20 — Bans the sale of common items containing PFAS (perfluoroalkyl and polyfluoroalkyl substances used to make food packaging grease- and water-resistant). The bill takes steps to restrict harmful phthalate and bisphenol chemicals from food packaging.

Virginia

HB1299 — Allows for the sale of to-go alcohol beverages until July 1, 2022.

HB1902 — Prohibits food vendors from using single-use expanded polystyrene food service containers. Requires chain restaurants to stop using such containers by July 1, 2023, and sets the date for compliance by all food vendors as July 1, 2025. A penalty will be inflicted of $50 a day for violators.

HB1973 — Allows nonprofits conducting online fundraisers to sell and ship wine in closed containers as part of a fundraising activity.

HB2068 — Establishes the Local Food and Farming Infrastructure Grant Program. The governor will award the grants based on infrastructure development projects that support local food production and sustainable farming.

HB2302 — Allows farmers markets to be treated as grocery stores during state of emergency and are allowed to remain open as essential businesses during a state of emergency declared by the Governor.

SB1188 — Establishes the Virginia Agriculture Food Assistance Program and Fund for Virginia farmers and food producers to donate, sell, or otherwise provide agriculture products to charitable food assistance organizations.

SB1193 — Establishes the Dairy Producer Margin Coverage Premium Assistance Program. Gives dairy farmers (with a resource management or nutrition management plan) the ability to receive a refund of their annual premium payment paid into the federal program.

SB1428 — Prohibits the Virginia Alcoholic Beverage Control Authority from selling in government stores low alcohol beverage coolers not manufactured by licensed distillers.

SB1471 — Allows the Board of Directors of the Virginia Alcoholic Beverage Control Authority to increase the frequency and duration of outdoor events that sell alcohol. The laws are expected to provide flexibility to restaurants during COVID-19.

Washington

HB1145 — Allows the use of non wood renewable fiber in recycled paper carryout bags.

HB1480 — Allows sale of to-go alcohol products, including cocktail kits and growlers.

HB5362 — Ensuring the funding of agricultural fairs.

SB5022 — Enacts recycling requirements for plastic beverage containers. Bans polystyrene (EPS) products and sets-up opt-in requirements for dining establishments using single-use foodware.

SB5272 — Waives a one-time annual liquor license and cannabis license fee for those establishments for 12 months.

West Virginia

SB 51 — Requires dairy foods processed in the state to be added to the list of items to be purchased by state-funded institutions.

SB 58 — Creates the West Virginia Farm Fresh Dairy Act.

Wisconsin

SB56 — Allows alcohol beverage retailers to make online or phone sales of alcohol beverages, to be picked up by the customers at a designated parking space that is not part of the retail licensed premises.

Wyoming

HB13 — Increases the amount of wine that a licensed out-of-state wine shipper may ship to any one household address. Allows Wyoming consumers to receive up to 12 cases of wine in a 12-month period (the former limit was four cases per year).

HB51 — Establishes grant program to meat processing facilities suffering during the COVID-19 pandemic.

HB54 — Focuses efforts and resources of the Wyoming Business Council on developing slaughter plant options for producers.

HB118 — Allows sale of eggs under the state’s Food Freedom Act.

HB156 — Allows winery permit holder to be issued an off-premise wine permit for a 24-hour period.

HB159 — Allows any liquor license holder — who then obtains an out-of-state shipper’s license — to ship alcohol to Wyoming households. Increases satellite permits for liquor manufacturers from one to two.

HB229 — Allows Wyoming ranchers the choice of selecting lawful forms of animal identification devices. Rejects USDA mandate to only use higher-cost RFID ear tags for livestock.

Food and Beverage Laws Passed in 2021

After the Covid-19 pandemic shortened their legislative sessions last year, lawmakers across the 50 states had a productive year in 2021. State leaders were able to pass hundreds of bills relating to food, beverages and food service.

Numerous new laws were aimed at helping restaurants survive — permitting permanent outdoor dining spaces, allowing carryout food services and to-go alcohol sales. Many of these regulations had been enacted in 2020 as temporary, emergency measures to aid restaurateurs, but expired this year.

This year was also big for cottage food laws. As more people experimented in their home kitchens during the pandemic, there was pressure to modernize cottage food laws. Over half the states updated their laws in 2021, regulating sales of homemade food.

Below are the key food, beverage and food service laws passed this year in, alphabetically, Alabama through Maryland. We’ll feature the balance of the states — Massachusetts to Wyoming — in TFA’s next newsletter (January 12, 2022).

Alabama

HB12 — Extends protections granted for cottage food businesses to include roasted coffees and gluten-free baking mixes.

HB539 — Increases the amount of alcohol which breweries and distilleries can sell to customers for off-premise consumption.

SB126 — Allows licensed state businesses to deliver wine, beer and spirits to customers’ homes.

SB160 — An update to Alabama’s cottage food law, SB160 allows for most non-perishable foods to be made in home-based food businesses without commercial licenses (instead of just only baked goods, jams/jellies, dried herbs and candies). It also removes the $20,000 sales limit for home-based food businesses. It also allows online sales and in-state shipping of products.

SB167 — Permits Alabama wineries to sell directly to consumers at special events.

SB294 — Authorizes wine manufacturers to sell directly to retailers without a distributor.

SB397 — Allows opening of wineries in Alabama’s 24 dry counties. The wineries will be allowed to produce and operate in a dry county, but they may not sell on premise.

Alaska

HB22 — Legalizes herd share agreements for the distribution of raw milk in the state.

Arizona

HB2305 — Amends law to allow two or more liquor producers, craft distillers or microbrewery licenses at one location.

HB2753 — States that licensed producers, craft distillers, brewers and farm wineries are subject to rules and exemptions prescribed by the FDA. Exempts production and storage spaces from state regulation.

HB2773 — Allows bars, liquor stores and restaurants to sell cocktails to-go.

HB2884 — Exempts alcohol produced on premise in liquor-licensed businesses from food safety regulation by the Arizona Department of Health Services, which adds rules regarding production, processing, labeling, storing, handling, serving, transportation and inspection. Specifies that this exemption includes microbreweries, farm wineries and/or craft distilleries.

Arkansas

HB118 — Permits the sale of cottage foods over the internet. Interstate sales are permitted if the producer complies with federal food safety regulations.

HB1228 — Allows for municipalities in dry counties to apply to be an entertainment district, just like in wet counties.

HB1370 — Establishes mead as an allowed liquor for a small farm winery — and allows wineries to ship mead. Also allows for mead to be taxed in the same manner as wine.

HB1426 — Establishes the Arkansas Fair Food Delivery Act, stating that a food delivery platform (like UberEats) must have an agreement with a restaurant or facility to take food orders and deliver food prepared.

HB1763 — Allows distilleries to self distribute their own products and allows out-of-state, direct-to-consumer shipments.

HB1845 — Restricts advertising alcohol in microbrewery-restaurants in dry counties.

SB248 — Replaces Arkansas’ cottage food law with the Food Freedom Act. Allows all types of non-perishable foods to be sold almost anywhere without a food safety license and certification, including grocery stores and retail shops.

SB339 — Allows permitted restaurants to sell on-the-go alcoholic beverages.

SB479 — Allows restaurants with alcohol beverage permits to expand outdoor dining without approval of the Alcoholic Beverage Control Division.

SB554 — Authorizes beer wholesalers to distribute certain ready-to-drink products.

SB631 — Authorizes a hard cider manufacturer to deliver hard cider.

California

AB61 — Allows restaurants and bars with alcohol licenses that added temporary, outdoor sidewalk dining spaces during the Covid-19 pandemic to continue serving alcohol in these spaces.

AB239 — Allows wineries to refill wine bottles at off-site tasting rooms, similar to breweries reusing growlers

AB286 — Requires third-party delivery companies to itemize cost breakdowns of delivery transactions to both restaurants and customers.

AB425 — Updates regulations regarding definitions, assessments, fees and funding mechanisms for the Dairy Council of California.

AB831 — Mandates that all labels on cottage food must include the disclaimer “Made in a Home Kitchen” along with the producer’s county and cottage food permit number.

AB941 — Establishes a grant program for counties to apply for farmworker resource centers, supplying farmworkers and their families information on education, housing, payroll, wage rights and health services.

AB962 — Requires the creation of a returnable bottle system in the state by 2024. Allows recyclable bottles to be washed and refilled by beverage producers rather than being crushed for recycling.

AB1144 — Updates California’s outdated cottage food laws, raising sales limit to either $75,000 (Class A permits) or $150,000 (Class B permits) and simplifying the approval process for sampling cottage food products. Also allows homemade food to be sold online.

AB1200 — By 2023, no eatery in California is permitted to distribute or sell food packaging that contains regulated perfluoroalkyl and polyfluoroalkyl substances or PFAS. Manufacturers of food packing must use the least toxic alternative when replacing their food packaging. Food packaging includes food or beverage containers, take-out containers, liners, wrappes, eating utensils, straws, disposable plates, bowls and trays.

AB1267 — Allows licensed manufacturers, distributors and sellers of alcoholic beverages to donate a portion of beverage purchases to a nonprofit.

AB1276 — Requires California eateries to only give take-out customers single-use utensils and condiment packets if they ask for them.

AR15 — Establishes Nov. 22 as Kimchi Day in the state.

SB19 — Allows wineries to open additional off-site tasting rooms without applying for a new license (former law allowed for only one off-site tasting room).

SB314 — Allows restaurants and bars that added temporary, outdoor sidewalk dining spaces during the Covid-19 pandemic a one-year grace period to apply for permanent expansion.

SB389 — Allows restaurants and bars to serve to-go alcohol alongside a meal.

SB453 — Establishes an Agricultural Biosecurity Fund specifically for the California State University system’s Agricultural Research Institute. The California State University’s 23 campuses and 8 off-campus branches can then use that fund to apply for grants related to supporting research on agriculture biosecurity, best practices around infectious agents hurting the state’s animal herds and plant crops.

SB517 — Authorizes a licensed beer manufacturer who obtains a beer direct shipper permit to sell and ship beer directly to a resident of the state for personal use.

SB535 — Makes it unlawful to manufacture or sell imitation olive oil in the state. Also restricts using “California Olive Oil” on a label unless 100% of the oil is derived from olives grown in California. The label can also only share that the oil comes from a specific region of California if at least 85% of the olives were grown in that region.

SB721 — Establishes Aug. 24 as California Farmworker Day.

Colorado

HB1027 — Extends sales of to-go alcohol from licensed restaurants and bars to 2026.

HB1162 — The Plastic Pollution Reduction Act, the law bans single-use plastic bags and containers made from polystyrene (styrofoam) for restaurants and other retailers by 2024. All stores will also implement a 10-cent bag fee for plastic and paper bags by 2023.

SB35 — Prohibits third-party restaurant delivery services from cutting pay to a driver to comply with fee limits. Also prohibits third-party delivery services from putting restaurants on their platforms without the eateries’ permission.

SB235 — Sends the Department of Agriculture $5 million for energy efficiency and soil health programs.

SB270 — Allows more Colorado wineries, cideries and distillers to attain a pub license and sell a variety of food in addition to their craft beverage. Current law puts small limits on the amount of craft drink made for a brewery to sell food, leaving out larger Colorado producers.

Connecticut

HB5311 — Enables permitted transporter to sell and serve alcohol on boats, motor vehicles and limousines.

HB6610 — Codifies expanded outdoor dining, allowing municipalities to close off streets and sidewalks for outdoor restaurant dining space.

SB894 — Allows patrons to pour their own alcoholic drinks at restaurants and bars. Will allow self-pour automated systems to be used in the state’s dining establishments.

HB6580 — Expands food agricultural literacy programs of study and community outreach, by increasing certification, education and extension programs with rural suburban and urban farms for students in grades Kindergarten through 12th grade.

Delaware

HB1 — Allows restaurants to continue selling to-go alcohol beverages. The bill also allows restaurants and bars to continue using outdoor dining spaces originally used during the Covid-19 pandemic.

HB46 — Allows brewery-pub and microbrewery license holders to brew, bottle and sell hard seltzers and other fermented beverages made from malt substitutes. Also includes a specific tax on fermented beverages.

HB143 — Reduces the amount of licensed taprooms to only one taproom within a ½ mile from another taproom.

HB212 — Increases minimum thickness for plastic bags (used by grocery stores and restaurants) to qualify as a reusable bag from 2.25 mils to 10 mils.

SB46 — Allows wedding venues and event centers licensed as bottle clubs to allow customers to bring alcoholic beverages on premise.

Florida

HB751 — Authorizes issuance of special licenses to mobile food vehicles to sell alcohol beverages within certain areas.

HB1647 — Allows more Orlando eateries to sell alcohol. Allows eateries with a smaller footprint (80-person capacity; formerly 150-person capacity) to sell beer, wine and spirits in six additional Orlando Main Street Districts.

SB46 — Increases production limits for distilleries from 75,000 gallons a year to 250,000 gallons. Eliminates the “six bottles per person per brand per year” requirement. Also allows craft distilleries to qualify for a vendor’s license to conduct tastings at Florida’s fairs, trade shows, farmers markets, expositions and festivals.

SB148 — Authorizes restaurants or bars also holding a public food service license to sell or deliver alcoholic beverages in sealed, to-go containers.

SB628 — Establishes a new program, the Urban Agriculture Pilot Project, to distinguish between traditional rural farms and emerging urban farms. Exempts farm equipment used in urban agriculture from being stored in certain boundaries.

SB663 — Updates Florida’s cottage food law to allow shipping of products, and raises the sales limit for shipped cottage food from $50,000 to $250,000. The bill also prevents counties or cities from banning cottage food businesses (Ed. note: Florida’s largest county, Miami-Dade, prohibits cottage food businesses).

SR2041 — Establishes a Food Waste Prevention Week in the state to acknowledge the importance of conserving food and preventing food waste.

Georgia

HB273 — Allows local municipalities to pass an ordinance, resolution or referendum election to authorize allowing a liquor store to open in their jurisdiction

HB392 — Allows a person to have a mixed cocktail or draft beer from the hotel delivered to their room by a hotel employee.

HB498 — Expands eligibility requirements for the state’s tax exemption for agricultural equipment and farm products. Any family-owned farm entity (defined as two or more unrelated, family-owned farms) can now share equipment, land and labor without losing ad valorem tax exemptions enjoyed by stand-alone family farms.

HB676 — Creates a legislative advisory committee on farmers’ markets (Farmers’ Markets Legislative Advisory Committee), made up of five members from the state’s Senate and House.

SR155 — Recognized February 17 as State Restaurant Day.

SB219 — Permits small brewers to sell alcohol for consumption on their premise. Allows state’s breweries to transfer beer between locations.

SB236 — Extends the Covid-era rule that allows restaurants to sell to-go alcohol.

Hawaii

HB817 — Requires state agencies to purchase an increasing amount of locally grown food.

HB237 — Earmarks $350,000 to the department of agriculture for the mitigation and control of the two-lined spittlebug, which has damaged nearly 2,000-acres of pasture land.

SB263 — Establishes a “Hawaii Made” program and trademark, to promote Hawaiian-made products.

Idaho

HB51 — Amends existing law to provide nutrient management standards on dairy farms. Allows dairy farmers the option of using phosphorus nutrients.

HB232 — Changes the distribution of tax on high-alcohol-content beer from the state wine commission to the state hop growers commission, helping promote the craft industry.

Illinois

HB2620 — Allows small breweries, meaderies and winemakers to distribute their products to local bars, grocery stores and liquor stores directly rather than through a third party.

HB3490 — Amends Illinois Food, Drug and Cosmetic Act, which says, if a restaurant includes milk as a default beverage in a kid’s meal, the drink must be dairy milk and contain no more than 130 calories per container or serving.

HB3495 — The Brewers Economic Equity & Relief Act, allows for limited brewpub self-distribution, permanent delivery for small alcohol producers, direct-to-consumer shipping for in-state and out-of-state brewers and distillers and self-distribution for manufacturers producing more than one type of alcohol.

HR33 — Creates the Illinois Good Food Purchasing Policy Task Force to study the current procurement of food within the state and explore how Good Food Purchasing can be implemented to maximize the procurement of healthy foods that are sustainably, locally and equitably sourced.

HR46 — Urges the Illinois Department of Agriculture to study the effects and the types of land loss to Black farmers. Calls for state support and capacity building for Black farming communities across the state and a dedication to helping grow agriculture in rural, urban, and suburban areas.

HR117 — Urges the United States Department of Agriculture and the United States Department of Commerce to increase the exportation of Illinois dairy products to other nations.

SB2007 — The Home-to-Market Act, updates the state’s Illinois Cottage Food Law. Expands sales avenues for cottage food producers, allowing sales at fairs, festivals, home sales, pick-up, delivery and shipping (cottage food was previously only allowed to be sold at farmers markets).

Indiana

HB1396 — Updates many of Indiana’s outdated alcohol laws, some from the Prohibition Era. Amended various sections of Indiana’s alcohol code impacting permittees, trade regulation and other various definitions.

HB2773 — Allows bars, liquor stores and restaurants to permanently sell to-go alcohol orders, originally allowed temporarily during the Covid-19 pandemic.

SB144 — Allows bulk wine purchasing limits for farm wineries to apply only to wine sold directly to a consumer and not to wine sold through a wholesaler. Also allows the holder of an artisan distiller permit to also hold a distiller’s permit.

SB185 — Creates a working group made up of industry organizations, food safety experts, Indiana State Department of Health, Indiana State Board of Animal Health and Indiana State Department of Agriculture to submit recommendations to the state concerning home-based vendors and cottage food laws.

Iowa

HB384 — Updates rules regarding alcohol licenses. Lengthens the hours of sale for alcoholic beverages on Sunday.

HF766 — Allows home delivery of alcoholic beverages from bars and restaurants by third-party delivery services, such as Uber or DoorDash.

Kansas

HB2137 — Allows bars, liquor stores and restaurants to permanently sell to-go alcohol orders, originally allowed temporarily during the Covid-19 pandemic.

Kentucky

HR3 — Recognizes March 23 as Agricultural Day in the state.

HR19 — Recognizes June as Dairy Month, honoring the state’s dairy workers.

SB15 — Allows a microbrewery licensee to sell and deliver up to 2,500 barrels of product to any retail licensee and to set forth terms of contracts between microbrewers and distributors.

SB67 — Allows bars, liquor stores and restaurants to permanently sell to-go alcohol orders, originally allowed temporarily during the Covid-19 pandemic.

Louisiana

HB192 — Authorizes credit card payment to manufacturers and wholesale dealers of alcoholic beverages (when previously cash was only allowed).

HB219 — Allows the delivery of ready-to-drink alcohol beverages (sold in manufacturer sealed containers), allowing brewers with a brewing facility to self-distribute.

HB269 — Allows authorized state employees to destroy meat, seafood, poultry, vegetables, fruit or other perishable food of foreign origin which are subject of a current import ban from the federal government.

HB291 — Allows self-distribution to any brewer who operates a brewing facility in the state.

HB706 — Adds microwinery to microdistillery permits.

HR104 — Designates May 19, 2021, as Louisiana Craft Brewers’ Day in the state.

HR210 — Authorizes a state subcommittee to study and make recommendations to the government on the regulation of the growing craft brewing industry in the state.

Maine

SB133 — Clarifies that licensed Maine manufacturers of spirits, wine, malt liquor and low-alcohol spirits products may sell and ship their products to a person located in another state.

SB205 — Allows bars and restaurants to permanently sell to-go alcohol orders through take-out and delivery services if the liquor is accompanied by a food order. Also temporarily permits licensed Maine distilleries that operate tasting rooms but do not operate licensed on-premise retail to sell spirits through take-out and delivery services accompanied by a food order.

SB306 — Temporarily waives certain requirements for relicensing for restaurants that serve liquor to help food establishments during the Covid-19 pandemic.

SB307 — Allows all Maine alcohol manufacturers to sell directly to out-of-state consumers (current law only allows wine to be sold out-of-state).

SB479 — Amends definition of “low-alcohol spirits product” by raising the maximum alcohol level of a low-alcohol spirits product from 8% to 15%.

SB630 — Prohibits shelf-stable products from being sold as cider. Products that do not require refrigeration or are heat-treated cannot be labeled as cider.

SB636 — Establishes the Local Foods Fund, which helps schools purchase produce and other minimally processed foods from local farmers and producers.

SB822 — An act affirming that food seeds are a necessity in the state.

Maryland

HB185 — Prohibits an alcoholic beverages license holder from requiring that an individual buy more than one bottle, container or other serving of alcohol at a time.

HB264 — Requires entities that generate at least two tons of organic waste per week to arrange for disposal alternatives, like reduction, donation, animal feed or composting.

HB269 — Establishes the Urban Agriculture Grant Program in the Department of Agriculture to increase the viability of urban farming and improve access to urban-grown foods.

HB 555 — Repeals a prohibition on allowing drugstores to apply for a liquor license.

HB1232 — Codifies emergency orders to grant permanent to-go delivery of alcohol and online shipment privileges.

SB205 — Authorizes local alcoholic beverage licensing boards to temporarily allow restaurants and bars to sell to-go alcoholic beverages. Also requires Maryland’s Alcohol and Tobacco Commission and the Maryland Department of Health to study expanding alcohol access.

SB821 — Codifies the governor’s 2020 executive order to grant alcohol delivery and shipment. Also allows permitting to serve alcohol at off-premise, special events.

A Yeast Primer

Brewers, winemakers and cidermakers are continually on the hunt for the ideal flavor profiles for their fermented beverages. And the key to manipulating those flavors is yeast.

“With beer, you’re taking this kind of gross, bitter soup of sweet barley and hops, and the yeast makes it taste good. Depending on the yeast that gets put in it, it can make it taste like 400 different things, so there’s so much potential there. I think that’s really exciting,” says Richard Preiss of Escarpment Laboratories. Priess was joined by Doug Checknita from Blind Enthusiasm Brewing and Patrick Rue from Erosion Wine Co. to discuss the world of yeast in TFA webinar, A Yeast Primer.

“If you’re invested in vegetable fermentation, yeast might be sort of clouded in mystery and something that is unwanted,” says Matt Hately, TFA advisory board member who moderated the webinar. “It’s what you live by in beverage fermentation in wine and beer and it’s the key to unlocking flavors to make that magic happen.”

Domesticated vs. Wild Yeasts

Just as dogs and cats were domesticated by humans, yeasts have been as well, says Priess, whose company makes and banks yeasts. They are microscopic organisms that adapt, “so if someone’s making beer for over the span of hundreds or thousands of years then the yeast is going to change to kind of get better at fermenting that beer and maybe it’s not going to be so good at surviving out in the wild, just like our toy poodle versus our wolf.”

Other fermented drinks, like wine, sake and cider, use different yeasts with their own specific sets of traits. This is why a wine yeast can’t be used in a beer and vice versa, “though there are some opportunities to experiment.”

Fermenting with wild yeasts has become increasingly in vogue with beer brewers. Aspirational brewers are finding yeasts on the skin of fruit or the bark of trees.

The panelists on the webinar praise experimentation, but note there is risk. Priess says yeasts designed to survive in the wild can be challenging to use in a beer. Checknita points out the safety factor in using yeasts directly from nature as well, “you can get stuff that’s harmful to human health so you have to be careful with your pH levels and what controls there are.”

Traditional winemakers, on the other hand, have long used the wild yeast on grapes to ferment. Rue notes that 10 years ago winemakers began to deviate from this tradition to use pure cultures instead. This process is how many large-scale, industrial producers operate today. But smaller winemakers, who often want to emphasize the specific traits of their terroir, generally use native yeasts and traditional winemaking techniques.

“It’s amazing how wine is how God intended wine to be made because you let nature happen and you’ll probably have a pretty good result with natural fermentation,” Rue continues, “where beer, it’s very touch-and-go, you have to have the perfect conditions and I’ve been able to do spontaneous fermentation with those yeasts.”

The Yeast Family Tree

There’s a large and continually-growing family tree of yeasts, with branches forming for genetic diversity and specialization.

Priess sees three new trends emerging in yeasts: traditional yeasts (like Norwegian kveik) being rediscovered, yeast hybridization (similar to cross-breeding a tomato) and genetic engineering to enhance certain traits of yeast.

“That’s the exciting part of what we’re doing is no one really knows the best approaches to using beer yeast yet, but there’s a lot more new science that’s happening, a lot more brewers that are experimenting, and together we’re collaborating to understand how to work with yeast better and kind of unlock new flavors and new possibilities,” Priess says.

Checknita agrees. He says new yeasts are forming new family trees through spontaneous fermentation, which is taking the base of a beer and experimenting to “push and change those yeasts to do what we want and get that clean flavor that’ll make a beer that tastes good to the human palate.”

- Published in Food & Flavor

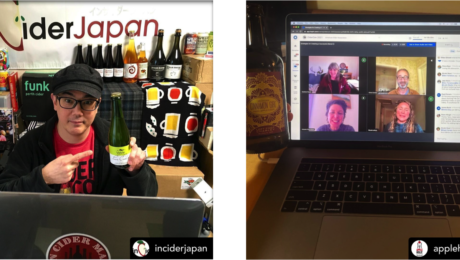

Are Cider Clubs Worth it?

In the past decade, more cideries have begun clubs as a way to connect with their customers, keep year-round sales and sell rare ciders.

But during 2020, when the COVID-19 pandemic closed taprooms and cancelled restaurant sales, cider clubs became critical to earn revenue. The American Cider Association (ACA) reported 22% of their members started a club in 2020.

“Our cider club was the one bright spot of 2020. That was really the one thing that kept growing, kept us motivated and got us excited,” says Talia Haykin, founder of Colorado-based Haykin Family Cider. Her products were sold in local fine dining establishments, but those sales evaporated during the pandemic.

“Everyone has kegs they can’t sell during the pandemic,” says Christopher Shockey, who co-authored the book The Big Book of Cider with wife Kirsten (a TFA Advisory Board member). “Cider clubs are keeping them afloat.”

Guaranteeing Sales & Creating Fans

Cider clubs are a subscription service where the cidery ships new, rare, seasonal or limited edition ciders to members multiple times a year. As both online shopping and access to direct-to-consumer alcohol shipping have expanded, subscriptions to cider, wine and other alcohol assortments have become feasible and increasingly popular.

“It’s taking customers who are already excited about you and converting them into a model that’s going to have them buy more from you regularly” says Eleanor Leger, founder of Eden Speciality Ciders. Leger and Haykin shared their tips on cider club growth opportunities during 2021 CiderCon.

“That’s money you know you’re going to have versus just duking it out on the store shelves where a new store manager can just decide they don’t want you and they want somebody else and you lose that shelf space,” Christopher says during the TFA webinar on “The State of the Art of Cidermaking.”

An ACA survey found that cider clubs generate up to 10% of a cidery’s total revenue.

Quarterly shipment of ciders is standard. Haykin and Leger advise cideries to ship more than twice a year, so members won’t forget they joined a club.

“You want to continually remind them that you exist,” Haykin says.

Shipping costs for cider — a fermented product which must be kept cold and is often sold in glass bottles — can be pricey. But, Haykin notes, even though he bears that high cost of shipping : “the repeat business of a club member is worth so much more to us.” Many clubs offer local pick-up to eliminate shipping costs.

Attracting & Keeping Customers

In the crowded alcohol market, cider clubs are a way to differentiate a brand.

While there are not specific stats on the demographics of Americans who subscribe to alcohol clubs, product subscription services overall are rapidly growing. Millennials are the dominant users of subscriptions — 31% currently have one or more, and another 38% say they will in the next six months.

Cider sales grew 9% in 2020, and they represent 11% of the craft beer category (where cider sales are tracked). Wine is struggling with Millenial and Gen Z consumers, who view it as a drink for an older demographic. Kirsten Shockey says younger consumers gravitate to cider instead.

“People are looking for funky flavors,” she adds. “I think the biggest battle cider makers have is feeling like the wine cooler crowd is their crowd. But that is changing, people are looking for more flavor.”

Member offerings vary for cider clubs, and can include:

- Discount on tap room products.

- First chance to try new items.

- Exclusive taproom tastings.

- Forage days (members help pick cider apples from local orchards).

- Volunteer opportunities at local farmers markets and food festivals.

The No. 1 reason people cancel a membership is because of a bad experience. Haykin stresses the importance of responding to a customer within, at most, 12 hours. “Communication is one of the most important things you’ll offer as a club,” she says.

Leger adds: “We jump all over someone who has had a problem to make sure they know we are sorry and we take care of it right away. Handling a problem really well creates incredible loyalty. People can be out there building your brand for you because they love you and they’re telling all their friends. If they have a bad experience, they’re destroying the brand for you.”

- Published in Business

How Does Yeast Interact with Cider Apples?

Researchers at Washington State University are developing a nutrient formula for yeast that could make fermentation easier and more predictable for cider makers.

“Cider apples don’t have as many nutrients for yeast, unlike grapes,” said Claire Warren, a microbiologist for WSU’s School of Food Science. “I want to make a nutrient base for yeast used with cider apples so fermentation can be more predictable batch to batch and year to year.”

The difference between hard cider and apple juice is the role of yeast. Yeast converts the sugar in cider apples into alcohol. Though much is known about how yeast interacts with grapes, little is known about how yeast interacts with apples. Researchers are studying the analytical information behind a cider apple, hoping their research will improve production.

Read more (Washington State University)

- Published in Science

7 Takeaways for Cideries in 2021

Despite a year when cideries around the world were forced to close down taprooms and cancel restaurant sales due to the pandemic, cider sales grew 9% in 2020.

“I know some of you are barely hanging on — but you are hanging on,” said Michelle McGrath, executive director of the American Cider Association (ACA). “We did not waver, we held our shares and we kept growing.”

McGrath presented industry statistics at CiderCon 2021, the ACA’s annual global cider conference. Because of the ongoing coronavirus pandemic, the conference was virtual this year. Nearly 800 people from 18 countries and 41 states attended the three-day conference.

Smaller, local cider brands sparked consumer interest in 2020. Sales of regional cider brands grew 33%, while national brands declined 6%.

The impact of the pandemic, though, has been severe on certain sectors of the industry. On-premise cider sales (in restaurants, breweries and taprooms) declined nearly 70% from 2019.

“We’re resilient, we’re tough, we’re savvy. You couldn’t have predicted how your business would have stood up to a once-in-a-lifetime pandemic,” said Anna Nadasdy, director of customer success at Fintech, a data company for the alcohol industry.

Nadasdy’s keynote on expected consumer trends in 2021 cited the key drivers influencing consumer behavior — the economy, politics and natural disasters. Here are seven of her takeaways for cideries:

- Consumers Buying all Alcohol Types

Though consumers have long been loyal to one type of alcohol — beer, wine or spirits — the “beer guy or wine gal” label is disappearing. Over one-third of consumers are purchasing from all three major categories.

Hard seltzer is the third largest beer segment (16% of dollar share, behind domestic premium and imported beers), but it’s the fastest growing. This is exciting for cider makers, Nadasdy notes — hard seltzer in 2018 was the size of the cider market today.

- Fruit-Flavored Cider is Growing

Though apple cider still dominates the cider market with 52% of sales, fruit-flavored cider grew three points in the past year to 12% of sales. The top three fruit-flavored products are: Ace Pineapple Craft Cider, Incline Scout Hopped Marionberry Cider and 2 Towns Ciderhouse Pacific Pineapple Cider.

(Other products in the cider category include: mixed flavors, dry cider, seasonal cider/perry, herb/spice cider.)

- Cider is Making Waves in Craft Beer

Cider — tracked as part of the overall craft beer category — is proving a worthy participant.Cider has 11% of the dollar share, second only to the category leader, India Pale Ale (41% of the market).

“That’s really impressive for such a small base,” Nadasdy says. “Even though you guys are a smaller segment, you still have a lot to contribute to the overall beer category. And I think it’s important when you’re having these conversations with retailers that you are able to point out these wins.”

- Hard Kombucha is Gaining Ground

Cideries are competing with hard kombucha. Though hard kombucha is a fermented tea and not a cider, retailers consider hard kombucha and cider comparable drinks. And hard kombucha sales are growing quickly.

“Although small now, keep an eye on (hard) kombucha,” Nadasdy said.

- Prepare for Changed On-Premise Sales

Once wide-spread vaccination is in place and on-premise dining returns, expect fundamental changes such as more online ordering, healthier menu choices and a rise in food tech like tablet menus. The National Restaurant Association listed other significant changes that will impact cideries:

- Streamlined menus. There will be fewer menu items, with 63% of fine dining operators and half of casual and family dining operators saying they will reduce their offerings.

- Alcohol-to-go. Seven in 10 full-service restaurants added alcohol-to-go during the pandemic. Thirty-five percent of customers say they are more likely to choose a restaurant that offers alcoholic beverages to-go.

- Rosé-Flavored Cider is Out

Every brand of rosé-flavored cider is losing sales. The top three brands showing the most significant losses in this category are: Angry Orchard, Bold Rock and Virtue.

- Cans Are King

Cans are leading the dollar share of the market, growing at 1.5 times the rate of bottles. Six-pack (11-13 ounce) cans are now the top share item with 29% of total cider sales. This is followed by six-pack (11-13 ounce) bottles and 4-pack (18-ounce) cans. (These figures do remove shares of Angry Orchard, which sells in bottles. Because Angry Orchard dominates 40% of the cider market, they skew the data.)

- Published in Business, Food & Flavor