Fermentation for Alternative Proteins

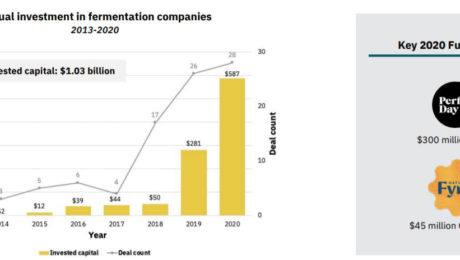

Investments in alternative protein hit their highest level in 2020: $3.1 billion, double the amount invested from 2010-2019. Over $1 billion of that was in fermentation-powered protein alternatives.

It’s a time of huge growth for the industry — the alternative protein market is projected to reach $290 billion by 2035 — but it represents only a tiny segment of the larger meat and dairy industries.

Approximately 350 million metric tons of meat are produced globally every year. For reference, that’s about 1 million Volkswagen Beetles of meat a day. Meat consumption is expected to increase to 500 million metric tons by 2050 — but alternative proteins are expected to account for just 1 million.

“The world has a very large demand for meat and that meat demand is expected to go up,” says Zak Weston, foodservice and supply chain manager for the Good Food Institute (GFI). Weston shared details on fermented alternative proteins during the GFI presentation The State of the Industry: Fermentation for Alternative Proteins. “We think the solution lies in creating alternatives that are competitive with animal-based meat and dairy.”

Why is Alternative Protein Growing?

Animal meat is environmentally inefficient. It requires significant resources, from the amount of agricultural land needed to raise animals, to the fertilizers, pesticides and hormones used for feed, to the carbon emissions from the animals.

Globally, 83% of agricultural land is used to produce animal-based meat, dairy or eggs. Two-thirds of the global supply of protein comes from traditional animal protein.

The caloric conversion ratios — the calories it takes to grow an animal versus the calories that the animal provides when consumed — is extremely unbalanced. It takes 8 calories in to get 1 calorie out of a chicken, 11 calories to get 1 calorie out of a pig and 34 calories to get 1 calorie out of a cow. Alternative protein sources, on the other hand, have an average of a 1:1 calorie conversion. It takes years to grow animals but only hours to grow microbes.

“This is the underlying weakness in the animal protein system that leads to a lot of the negative externalities that we focus on and really need to be solved as part of our protein system,” Weston says. “We have to ameliorate these effects, we have to find ways to mitigate these risks and avoid some of these negative externalities associated with the way in which we currently produce industrialized animal proteins.”

What are Fermented Alternative Proteins?

Alternative proteins are either plant-based and fermented using microbes or cultivated directly from animal cells. Fermented proteins are made using one of three production types: traditional fermentation, biomass fermentation or precision fermentation.

“Fermentation is something familiar to most of us, it’s been used for thousands and thousands of years across a wide variety of cultures for a wide variety of foods,” Weston says, citing foods like cheese, bread, beer, wine and kimchi. “That indeed is one of the benefits for this technology, it’s relatively familiar and well known to a lot of different consumers globally.”

- Traditional fermentation refers to the ancient practice of using microbes in food. To make protein alternatives, this process uses “live microorganisms to modulate and process plant-derived ingredients.” Examples are fermenting soybeans for tempeh or Miyoko’s Creamery using lactic acid bacteria to make cheese.

- Biomass fermentation involves growing naturally occurring, protein-dense, fast-growing organisms. Microorganisms like algae or fungi are often used. For example, Nature’s Fynd and Quorn …mycelium-based steak.

- Precision fermentation uses microbial hosts as “cell factories” to produce specific ingredients. It is a type of biology that allows DNA sequences from a mammal to create alternative proteins. Examples are the heme protein in an Impossible Foods’ burger or the whey protein in Perfect Day’s vegan dairy products.

Despite fermentation’s roots in ancient food processing traditions, using it to create alternative proteins is a relatively new activity. About 80% of the new companies in the fermented alternative protein space have formed since 2015. New startups have focused on precision fermentation (45%) and biomass fermentation (41%). Traditional fermentation accounts for a smaller piece of the category (14%). There were more than 260 investors in the category in 2020 alone.

“It’s really coming onto the radar for a lot of folks in the food and beverage industry and within the alternative protein industry in a very big way, particularly over the past couple of years,” Weston says. “This is an area that the industry is paying attention too. They’re starting to modify working some of its products that have traditionally maybe been focused on dairy animal-based dairy substrates to work with plant protein substrates.”

Can Alternative Protein Help the Food System?

Fermentation has been so appealing, he adds, because “it’s a mature technology that’s been proven at different scales. It’s maybe different microbes or different processes, but there’s a proof of concept that gives us a reason to think that that there’s a lot of hope for this to be a viable technology that makes economic sense.”

GFI predicts more companies will experiment with a hybrid approach to fermented alternative proteins, using different production methods.

Though plant-based is still the more popular alternative protein source, plant-based meat has some barriers that fermentation resolves. Plant-based meat products can be dry, lacking the juiciness of meat; the flavor can be bean-like and leave an unpleasant aftertaste; and the texture can be off, either too compact or too mushy.

Fermented alternative proteins, though, have been more successful at mimicking a meat-like texture and imparting a robust flavor profile. Weston says taste, price, accessibility and convenience all drive consumer behavior — and fermented alternative proteins deliver in these regards.

And, compared to animal meat, alternative proteins are customizable and easily controlled from start to finish. Though the category is still in its early days, Weston sees improvements coming quickly in nutritional profiles, sensory attributes, shelf life, food safety and price points coming quickly.

“What excites us about the category is that we’ve seen a very strong consumer response, in spite of the fact that this is a very novel category for a lot of consumers,” Weston says. “We are fundamentally reassembling meat and dairy products from the ground up.”

- Published in Business, Food & Flavor, Health, Science

Study: Can Fermented Veggies Impact Health?

Is there a connection between a happy gut and a healthy heart? The University of North Florida Department of Nutrition and Dietetics is conducting a study to determine what impact a diet rich in fermented vegetables has on cardiovascular disease and markers of inflammation.

Participants will be placed in two groups — the first consumes their regular diet for eight weeks, then receives fermented vegetables at the end of the study. The second will eat a half cup of fermented vegetables every day for eight weeks.

“These studies are the only way nutritionists can determine if certain foods can help with prevention and/or treatment of common health problems faced by our community, such as cardiovascular disease,” says Dr. Andrea Arikawa, associate professor at the university.

Read more (University of North Florida)

What’s the Actual Probiotic Count of Commercial Kefir?

A new peer-reviewed study from researchers at the University of Illinois and Ohio State University found 66% of commercial kefir products overstated probiotic count and “contained species not included on the label.”

Kefir, widely consumed in Europe and the Middle East, is growing in popularity in the U.S. Researchers examined the bacterial content of five kefir brands. Their results, published in the Journal of Dairy Science, challenge the “probiotic punch” the labels claim.

“Our study shows better quality control of kefir products is required to demonstrate and understand their potential health benefits,” says Kelly Swanson, professor in human nutrition in the Department of Animal Sciences and the Division of Nutritional Sciences at the University of Illinois. “It is important for consumers to know the accurate contents of the fermented foods they consume.”

Probiotics in fermented products are listed in colony-forming units (CFUs). The more probiotics, the greater the health benefit.

According to a news release from the University of Illinois: “Most companies guarantee minimum counts of at least a billion bacteria per gram, with many claiming up to 10 or 100 billion. Because food-fermenting microorganisms have a long history of use, are non-pathogenic, and do not produce harmful substances, they are considered ‘Generally Recognized As Safe’ (GRAS) by the U.S. Food and Drug Administration and require no further approvals for use. That means companies are free to make claims about bacteria count with little regulation or oversight.”

To perform the study, the researchers bought two bottles of each of five major kefir brands. Bottles were brought to the lab where bacterial cells were counted and bacterial species identified. Only one of the brands studied had the amount of probiotics listed on its label.

“Just like probiotics, the health benefits of kefirs and other fermented foods will largely be dependent on the type and density of microorganisms present,” Swanson says. “With trillions of bacteria already inhabiting the gut, billions are usually necessary for health promotion. These product shortcomings in regard to bacterial counts will most certainly reduce their likelihood of providing benefits.”

The news release continues:

When the research team compared the bacteria in their samples against the ones listed on the label, there were distinct discrepancies. Some species were missing altogether, while others were present but unlisted. All five products contained, but didn’t list, Streptococcus salivarius. And four out of five contained Lactobacillus paracasei.

Both species are common starter strains in the production of yogurts and other fermented foods. Because those bacteria are relatively safe and may contribute to the health benefits of fermented foods, Swanson says it’s not clear why they aren’t listed on the labels.

Although the study only tested five products, Swanson suggests the results are emblematic of a larger issue in the fermented foods market.

“Even though fermented foods and beverages have been important components of the human food supply for thousands of years, few well-designed studies on their composition and health benefits have been conducted outside of yogurt. Our results underscore just how important it is to study these products,” he says. “And given the absence of regulatory scrutiny, consumers should be wary and demand better-quality commercial fermented foods.”

The Safety of Fermented Food

Thanks to lactic acid — which kills harmful bacteria during fermentation — fermented foods are arguably among the safest foods that humans eat. But if critical errors are made, there is the risk of food safety hazards.

“When we talk about fruit and vegetable ferments, there is a very long history of microbial safety with traditionally fermented fruits and vegetables,” says Erin DiCaprio, extension specialist at University of California, Davis, Department of Food Science and Technology. “While outbreaks associated with fermented fruits and vegetables are rare, vegetable and fruit fermentation is not without risk.”

DiCaprio, a food safety expert, detailed proper food safety protocols during a webinar for EATLAC, a UC Davis project putting scientific knowledge and research behind fermentation. DiCaprio shared two documented instances of fermented foods causing a foodborne illness, both from small-scale batches of kimchi. But she emphasized that, when all food safety concerns are mitigated, fermented foods do not pose a risk.

“From the food microbiology standpoint, bacteria really are the most important group of microorganisms because bacteria, certain types of bacteria, are a food safety concern,” she adds. “There are many different types of bacteria that contribute to food spoilage and, of course, there are specific types of bacteria that are used beneficially for fermentation.”

What happens during fermentation that makes food safe? Lactic acid bacteria are created, which convert sugars into lactic acid, acetic acid and CO2. Those antimicrobial compounds help fight off pathogens, competing with other microbes for nutrition sources.

Biological hazards — bacteria, viruses and parasites that can cause foodborne illnesses — are the biggest concerns. Botulism, E. coli and salmonella are the main hazards for fermented foods. Botulism can form in oxygen-free conditions if a fermentation is not successful and acid levels are too low. E. coli and salmonella form when sanitation practices are not followed.

“Commercially, when someone is developing a valid fermentation process, they are typically going to be looking to see that sufficient acid is produced during fermentation, to inactivate some of these acid tolerant (bacteria),” DiCaprio says. “Our traditional vegetable fermentations — things like fermented cucumber, sauerkraut, kimchi — they’ve all been shown to produce sufficient acid to inactivate the sugar toxin producing e-coli, so from a safety standpoint, sufficient acid production is the critical control point for ensuring the safety of a fermented fruit or vegetable. “

There are seven critical factors to keep a ferment safe:

- High-quality, raw ingredients. “If there are a high number of spoilage microorganisms to start with, it will be really difficult for the lactic acid bacteria to dominate the fermentation,” DiCaprio says.

- Research-based recipe. Following a tested recipe ensures the proper balance of ingredients to keep the food safe.

- Proper sanitation. Cleaning of all utensils and surfaces ensures no pathogens will contaminate the food. This mitigates cross-contamination risk, too.

- Preparation of ingredients. Food particles should be uniform in size, either cut in small slices or shredded. Smaller pieces release more water and nutrients, promoting the growth of lactic acid bacteria.

- Salt concentration. Lactic acid bacteria thrive in a salt brine. The key amount: anywhere from 1-15% salt brine by weight of the ferment.

- Appropriate temperature. A temperature between 65-75 degrees fahrenheit is ideal to keep spoilage microorganisms at bay.

- Adequate time. “It takes a while for significant acid to be produced, so be patient and follow the directions in the recipe,” DiCaprio advises. Most fruit and vegetable ferments take 3-6 weeks to be completed.

Solving Illnesses with Fermentation?

Scientists in Russia and Egypt have developed a functional drink that’s been proven to combat anemia and malnutrition. The juice is made from beet extract, milk and probiotic bacterial strains. The scientists developed a quinoa bread, too. The goal is to keep the beverage and bread affordably priced and get them offered at grocery stores internationally.

“One should bear in mind that we are not creating a medicine, but a natural, functional food product,” said Sobhi Ahmed Azab Al-Suhaimi, professor in the Department of Technology at South Ural State University (SUSU) in Russia. “However, this juice can make up for the lack of iron, zinc, manganese and calcium in the body. One serving of the drink will contain the whole rate [sic] of minerals. Its carbohydrate content is low. Fermented juice will help to overcome anemia and to improve digestion due to probiotics.”

Scientists at SUSU worked with scientists at the University of Alexandria in Egypt. Their findings were published in the Journal of Food Processing and Preservation and Plants.

Read more (Phys.org)

Fermenting — in Space?

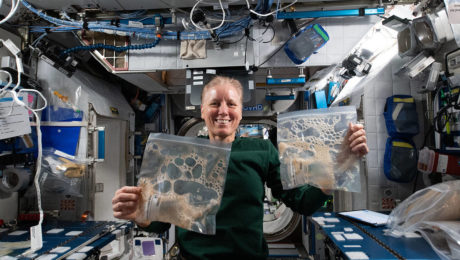

Microbes that coexist on plants influence a crop’s size, shape, color, flavor and yield. What would these microbes do in microgravity? The International Space Station (ISS) is testing to find these results.

Flight engineer Shannon Walker (pictured) shows sample bags collected for the Grape Juice Fermentation in Microgravity Aboard ISS study. Astronauts will observe the fermentation process, measuring microbial differences. Back on earth, a matching, control sample is being observed in an environmental control chamber that mimics the ISS ambient temperature. The space and earth samples then will be analyzed for changes. Both flight and ground control samples are analyzed post-investigation for genetic change.

Read more (NASA)

“One Grain to Bind Them All”

A new study on kefir found that the individual dominant species of Lactobacillus bacteria in kefir grains cannot survive in milk on their own. The bacteria need one another to create the fermented dairy drink, “feeding on each other’s metabolites in the kefir culture.”

The research, conducted by EMBL (Europe’s laboratory for life and sciences) and Cambridge University’s Patil group and published in Nature Microbiology, illustrates a dynamic of microbes that had eluded scientists. Though scientists knew microorganisms live in communities and depend on each other to survive, “mechanistic knowledge of this phenomenon has been quite limited,” according to a press release on the research.

“Cooperation allows them to do something they couldn’t do alone,” says Kiran Patil, group leader and author of the paper. “It is particularly fascinating how L. kefiranofaciens, which dominates the kefir community, uses kefir grains to bind together all other microbes that it needs to survive — much like the ruling ring of the Lord of the Rings. One grain to bind them all.”

To make kefir, it takes a team. A team of microbes.

The group studied 15 samples of kefir, one of the world’s oldest fermented food products. Below are highlights from a press release on the published results.

A Model of Microbial Interaction

Kefir first became popular centuries ago in Eastern Europe, Israel, and areas in and around Russia. It is composed of ‘grains’ that look like small pieces of cauliflower and have fermented in milk to produce a probiotic drink composed of bacteria and yeasts.

“People were storing milk in sheepskins and noticed these grains that emerged kept their milk from spoiling, so they could store it longer,” says Sonja Blasche, a postdoc in the Patil group and an author of the paper. “Because milk spoils fairly easily, finding a way to store it longer was of huge value.”

To make kefir, you need kefir grains, which must come from another batch of kefir. They cannot be made artificially. The grains are added to milk, to ferment and grow. Approximately 24 to 48 hours later (or, in the case of this research, 90 hours later), the kefir grains have consumed the available nutrients. The grains have grown in size and number, and are removed and added to fresh milk — to begin the process anew.

For scientists, kefir is more than just a healthy beverage: it’s an easy-to-culture model microbial community for studying metabolic interactions. And while kefir is quite similar to yogurt in many ways – both are fermented or cultured dairy products full of ‘probiotics’ – kefir’s microbial community is far larger, including not just bacterial cultures but also yeast.

A “Goldilocks Zone”

While scientists know that microorganisms often live in communities and depend on their fellow community members for survival, mechanistic knowledge of this phenomenon has been quite limited. Laboratory models historically have been limited to two or three microbial species, so kefir offers – as Patil describes – a ‘Goldilocks zone’ of complexity that is not too small (around 40 species), yet not too unwieldy to study in detail.

Blasche started this research by gathering kefir samples from several sources. Though most were obtained in Germany, they may have originated elsewhere, grown from kefir grains passed down through the years..

“Our first step was to look at how the samples grow. Kefir microbial communities have many member species with individual growth patterns that adapt to their current environment. This means fast- and slow-growing species and some that alter their speed according to nutrient availability,” Blasche says. “This is not unique to the kefir community. However, the kefir community had a lot of lead time for coevolution to bring it to perfection, as they have stuck together for a long time already.”

Cooperation is key

Finding out the extent and nature of cooperation among kefir microbes was far from straightforward. Researchers combined a variety of state-of-the-art methods, such as metabolomics (studying metabolites’ chemical processes), transcriptomics (studying the genome-produced RNA transcripts) and mathematical modelling. These processes revealed not only key molecular interaction agents like amino acids, but also the contrasting species dynamics between grains and milk.

“The kefir grain acts as a base camp for the kefir community, from which community members colonise the milk in a complex yet organised and cooperative manner,” Patil says. “We see this phenomenon in kefir, and then we see it’s not limited to kefir. If you look at the whole world of microbiomes, cooperation is also a key to their structure and function.”

In fact, in another paper from Patil’s group (in collaboration with EMBL’s Bork group) in Nature Ecology and Evolution, scientists combined data from thousands of microbial communities across the globe – from in soil to in the human gut – to understand similar cooperative relationships. In this second paper, the researchers used advanced metabolic modelling to show that the co-occurring groups of bacteria, groups that are frequently found together in different habitats, are either highly competitive or highly cooperative. This stark polarization hadn’t been observed before, and sheds light on evolutionary processes that shape microbial ecosystems. While both competitive and cooperative communities are prevalent, the cooperators seem to be more successful in terms of higher abundance and occupying diverse habitats — stronger together!

Fermented Foods Fighting Food Insecurity

Fermenti Foods has teamed up with a local salt producer to help food insecurity in their local county of Madison County, North Carolina.

Meg Chamberlain (pictured) donates jars of her fermented kraut and carrots to the Beacon of Hope Food Bank. She’s also helped the food bank preserve fresh food donations. And now she’s adding recipes for sauerkraut and tutorials on YouTube. Chamberlain says fermentation is a useful tool for home preservation.

“In addition to the fact that more people are growing, they need to know what to do with what they’re growing in their gardens,” she said.

Read more (Citizen Times)

Chocolate’s Beer Roots

Chocolate beer sounds like a faddish flavor, but its roots run deep. Pre-Columbian Mesoamericans fermented cacao fruit to make a beer-like drink called chicha.

“Chicha is usually made from corn, but there are regional variations made from other new-world plants like potatoes, peanuts and cacao beans,” reads an article from The Seattle Times. Chicha was studied by archaeology professors at Cornell and Berkeley who found “The roots of the modern chocolate industry can be traced back to this primitive fermented drink.”

Read more (The Seattle Times)

Cautionary Notes about Probiotics

Do probiotic supplements deliver the same benefits as fermented foods? Dr. Gail Cresci says to be leery of prebiotic and probiotic pills.

“There are challenges to keeping microbes viable in encapsulated tablets,” says Cresci, director of Nutrition Research for the Cleveland Clinic’s Department of Pediatric Gastroenterology, Hepatology and Nutrition. “It’s also very, very important to know that each strain of bacteria is not the same as the next. For example, lactobacillus has hundreds of different strains, and each one may behave differently. People like to use supplements because they like to think one size fits all, but it doesn’t.”

“Take in prebiotics and probiotics through food sources. Yogurt with added probiotic bacterial strains is much better to consume than supplements also because as it’s been waiting for you to eat it, it’s been producing more beneficial metabolites. When you eat it, you get all that.”

Read more (American Heart Association/U.S. News & World Report)