Ugly Fruit into Delicious Kombucha

A new Los Angeles-based kombucha brand has a unique approach to their fermented tea. Sunset Cultures owner and chef Balo Orozco (pictured) uses the unsold or “ugly” fruits and vegetables from local farms into “some of L.A.’s most creative kombuchas, hot sauces and condiments.”

Staying true to his goal of curbing food waste and helping local farmers is certainly not easy. Orozco spends much of his days driving across the state to pick up boxes or pallets of produce that would otherwise be thrown away or composted. Another challenge: the kombucha flavors and condiment offerings change with the amount and type of surplus product Orozco receives from farmers. (Sunset Cultures does consistently sell four core kombucha flavors).

Orozco’s roots are in the restaurant industry. As a chef, he was alarmed at the amount of kitchen waste restaurants would throw away. His specialty soon switched to reusing kitchen scraps and fermenting house-produced condiments. After the last restaurant he worked at folded due to the pandemic, he began working on Sunset Cultures.

Sunset Cultures products are always changing and adapting based on available products. In the last six months, Sunset Cultures began making jam, a solution to their own wasted byproduct from the lightly boiled strawberries used in their kombucha.

Sunset Cultures products are currently sold in 40 retail shops and online, with plans to expand to other cities in 2023.

Read more (Los Angeles Times)

- Published in Food & Flavor

Froyo’s Comeback

Frozen yogurt has been victim to trending food cycles for decades, first coming to America in the 80s, experiencing a boom in the 90s, then again in the early 2000s. Now industry leader say froyo is poised for its second (fourth?) act, thanks to the healthy ice cream alternative trend and wellness-focused product boom. And froyo this time around will be different.

“This trend will only grow stronger,” says Sam Yoon, president of froyo chain Yogurtland. Sales at Yogurtland were up 27% in 2021. “Frozen yogurt is healthier and contains probiotics that boost immune systems. Our frozen yogurt contains at least 10 million cultures at the time of manufacturing, and our flavors are developing around plant-based flavors our guests love, as well as sugar-free options.”

Plan for modern froyo shops to use high-quality ingredients, offer dairy-free options, highlight yogurt’s fermented and probiotic punch, utilize tech-driven self-service machines, partner with CPG brands and create diverse, global flavors.

“Millennials love the brand in New York, so we’ll keep playing to that,” Hershman adds. “For (Millennials), they grew up with frozen yogurt always being available, so to have a cool, clean kind of modern, sleek store to go to that sells frozen yogurt, versus kind of a dingy local shop, is a nice benefit,” says Neil Hershman, the largest franchisee of froyo shop 16 Handles.

Read more (QSR Magazine)

- Published in Food & Flavor

Fermenting Sustainable Food

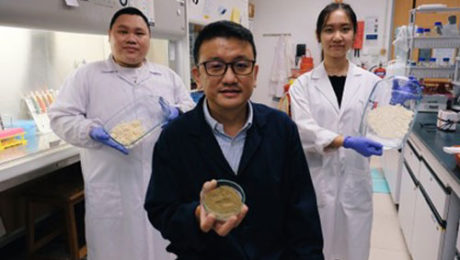

The food industry is at the center of multiple bottlenecks hurting food production – global food crisis, extreme weather, supply chain disruption, inflation and geopolitical conflict. Researchers at Singapore’s prestigious Nanyang Technological University (NTU) have found a sustainable food solution: fermentation.

An article in New Food Magazine details the fermentation innovations of NTU and how they’re fermenting the edible by-products of food manufacturing to produce new food. Their food studies found great promise in okara (the “insoluble remains of soybeans from the production of soy milk and beancurd”) and spent grain (the “residual barley pulp from the beer industry”).

“Fermentation is a way to repurpose okara, a major food manufacturing side stream that is often discarded, and transform it into a highly nutritious food,” says Dr. Ken Lee (pictured), senior lecturer at NTU’s School of Chemistry, Chemical Engineering and Biotechnology, who led a study published in LWT – Food Science and Technology.

The study showed okara fermented with a mixed culture of the fungus Aspergillus oryzae and the bacterium Bacillus subtilis made a nutritional-rich food. This inoculated fermentation process is also used to make soy sauce.

Fermenting spent grain also makes a nutrient-rich, upcycled food: a protein-rich food emulsifier. A separate study by NTU researchers published in Food Chemistry found that plant-based food can replace dairy and eggs in condiments like mayonnaise, dressings and whipped cream.

“Upcycling food waste such as spent grain for human consumption is an opportunity for enhancing processing efficiency in the food supply chain, as well as potentially promoting a healthier plant-based protein alternative to enrich diets,” says Professor William Chen, professor and director of NTU’s Food Science and Technology Programme.

Read more (New Food Magazine)

- Published in Science

Is Water Kefir Drink of 2023?

Water kefir or tibicos is making a splash. Food trend analysts are highlighting tibicos as the “it” drink of the new year.

Tibicos is ripe for popularity in 2023. More consumers are shunning soda in favor of functional drinks. Tibicos is not sugar-filled like soda, not as tart at kombucha and more flavor-filled than seltzer water.

An article on Yahoo notes that water kefir has a unique taste compared to other fermented drinks like kombucha or kvass. “Tibicos is knows as a ‘softer’ fermented beverage because of its lactic acid,” the article reads.

The growing trend is worth highlighting, but TFA notes the Yahoo article got a few facts wrong — like the spelled of kvass and chicha (a fermented soda). Also, though the article states the microbiota of tibicos contains different acids, yeast is not one of them. Yeast will never produce acid.

Read more (Yahoo)

- Published in Food & Flavor

Slow Burn Serves Travelling Ferments

Hear the origin story of traveling restaurant Slow Burn and you’ll wonder what’s the meaning behind the name. Chefs practice zero waste through slow cooking methods, fermenting, preserving and dehydrating scraps to use as an ingredient in the next sustainable meal. The chefs founded Slow Burn after feeling frustrated with the traditional restaurant industry, from the exhausting grind to the amount of food waste.

Slow Burn will travel through California’s coast this fall and winter, then head to multiple cities in Canada. Husband-and-wife duo Andy Doubrava and Tiffani Ortiz drive to each location towing a “trailer full of their carefully packed jars of fermented sauces, pickled produce and whatever else they’ve smoked and preserved, then travel from kitchen to kitchen. Whatever isn’t utilized at one event will appear on the next menu, or the next — sometimes as an oil, sometimes a relish, sometimes as part of a dessert in the name of creative waste mitigation, and hopefully, building awareness and community around it.”

Of their food cost, 65% goes towards what’s plated, while 35% goes toward future meals. In addition to creating new ingredients out of food scraps, they’re using waste to compost, dye merchandise and create soaps from the kitchen grease.

Unsure how guests would respond to a roaming, sustainable restaurant, Doubrava and Ortiz were surprised at the amount of tickets purchased through the 2022 – and the amount of invitations from chefs around the world.

“It’s really hard to put what we do in a box,” Ortiz told the Los Angeles Times. “I had to put ‘international food’ on our Tock page because how do you explain to people the weird s— we’re doing sometimes? It doesn’t sound good when you say that we’re fermenting rhubarb, but it’s kind of one of those things where when they’re here, they understand.”

Read more (Los Angeles Times)

- Published in Food & Flavor

Could Primeval Sake Variety Revive the Drink?

As Japanese consumers continue to swap beer, wine and cocktails over sake, the country’s national drink, industry experts think the doburoku sake variety could revive the dwindling sake market.

Doburoku is the catch-all term for sake that is unfiltered and gently carbonated. Described as rustic, cloudy and soupy, the drink’s brewing process doesn’t follow traditional sake rules. Brewers experiment with flavors, making it sweet or savory. It’s a “hyperlocal expression of soil and culture is its trademark,” reads an article on digital beverage publication Punch. Doburoku is typically unpasteurized, brewed in small batches.

There are only around 200 doburoku brewers in Japan, many who are farmers running small inns and restaurants. Only about two dozen of Japan’s 1,500 sake brewers make doburoku.

“At Heiwa Doburoku Kabutocho Brewery, the drink comes plain or aged, but also with unusual variations: dry-hopped, infused with matcha, mashed with persimmons, or blended with azuki beans, in part to tone down the alcoholic sharpness that many among sake’s detractors find off-putting,” continues the article. After fermenting the rice, koji and yeast for about two weeks, most of Heiwa’s doburoku is made in 7-liter pots in a backroom of the bar.

Norimasa Yamamoto, Heiwa Shuzou’s fourth-generation president, hopes to generate interest in sake by putting a “modern spin on the old-fashionred drink. …I’m hoping that, once you’ve tried doburoku, you’ll become curious enough about our rice fermentation tradition to delve into sake,” he says.

Read more (Punch)

- Published in Business, Food & Flavor

Microbes in Cheese

Do you love a mild mozzarella, a salty Parmesan or a funky brie? Thank microbes.

Though the thousands of varieties of the world’s cheeses all begin as a white lump of curd, the diversity is astounding. From the flavor to the color to the texture, cheese goes from “uniform blandness to this cornucopia” thanks to bacteria, yeasts and molds. An article in Smithsonian Magazine – titled The Science Behind Your Cheese – shares the details.

“More than 100 different microbial species can easily be found in a single cheese type,” says Baltasar Mayo, a senior researcher at the Dairy Research Institute of Asturias in Spain.

Scientists have only recently begun to study the microbial nature of cheese. To find out the bacteria and cheese present, scientists extract DNA from the cheese, then match it to genes in the database.

“The way we do that is sort of like microbial CSI, you know, when they go out to a crime scene investigation, but in this case we are looking at what microbes are there,” says Ben Wolfe, a microbial ecologist at Tufts University.

Though cheesemakers often add starter cultures of beneficial bacteria to fresh curds to transform it into a delicious cheese, Wolfe’s team found the microbiomes of the cheese “showed only a passing resemblance to those cultures. Often, more than half of the bacteria present were microbial ‘strangers’ that had not been in the starter culture,” continues the article.

Those “strangers” dumbfounded researchers. Microbes like Brachybacterium found in Gruyère are more commonly found in soil, seawater and chicken litter. Or the Halomonas most commonly found in salt ponds and marine environments. Or, Brevibacterium linens found in damp areas of skin, such as between the toes. Those bacteria come from the environment of the cheesemaking facilities. The microbes come from the cow, goat or sheep, the bacteria in the farm’s stable, the skin bacteria from the hand of the milker, the microbes in the dairy storage tank and/or the sea salt in the brine used to wash down the cheese. Hundreds of bacteria have been detected in long-ripened cheeses.

“Furthermore, by repeatedly testing, scientists have observed that there can be a sequence of microbial settlements whose rise and fall can rival that of empires,” continues the article.

Modern cheesemaking is, sadly, more controlled, meaning modern cheese isn’t as flavorful. Cheesemaking has “become tamer over time,” cleaner and more sterilized, filtered, pasteurized, machine operated.

“Many of our cheddars, provolones and Camemberts, once wildly proliferating microbial meadows, have become more like manicured lawns. And because every microbe contributes its own signature mix of chemical compounds to a cheese, less diversity also means less flavor — a big loss.”

Read more (Smithsonian Magazine)

- Published in Food & Flavor, Science

Exploring Culinary Bubbles

Serious Eats features a series of articles on fermented drinks in their latest digital issue, “Bubbles.” Bubbles are the “negative space” in food which contribute to food flavor and fermentation. The long-form articles dive into kombucha, tepache, coffee and explore how the beer industry is adapting with a CO2 shortage.

“It’s easy to look past the pockets of air that occupy so much of what we eat, but food as we know it wouldn’t be recognizable without them,” reads the editor letter describing the new article series. “Bubbles inflate breads, lighten cakes and batters, aerate creams and mousses, and add fizz to so many drinks. They’re a byproduct of fermentation, a critical determinant of texture, the thing that makes your eyes water as you let out an Aaahhhhhhhhhh after that first spicy sip of cold soda or beer. So much of what defines our food is all the stuff that’s not there.”

Read more (Serious Eats)

- Published in Food & Flavor

Fermentation Tops Restaurant Trend List

“Pickling and fermenting preparations are having a moment,” reads the 2023 Foodservice Industry Trend Report from Technomic. The food trend forecaster’s annual list rates fermentation “The Power of Preserving” as one of their top seven industry trends.

“Not only do these preparations promote ingredient preservation and health connotations but they also allow for unique culinary experimentation,” the report reads.

Technomic anticipates fermented food crafts at the bar, like kombucha, miso and sake. But lacto-fermentation, they predict, will also make its way to the menu, as restaurants detail their preserving processes “to provide consumers with a level of scientific transparency.”

Read more (Technomic)

- Published in Food & Flavor

Poland Becomes Europe’s Kimchi Hub

The world’s largest kimchi producer – Daesang Corporation – is building their first European factory in Poland.

Daesang is investing $10.6 million to build the Kraków facility. It is a joint venture – called Daesang ChPN Europe – with Polish food producer Charsznickie Pola Natury (ChPN), who specializes in fermented foods. It will be the Korean company’s 11th overseas production facility – one facility is in the U.S. and the others are in China. They plan to produce 3,000 tons of kimchi a year.

“The Polish joint venture is yet another adventure for our attempts to globalize kimchi,” said Lim Jung-bae, CEO of Daesang. “We will do our best to promote the excellence and legitimacy of kimchi in Europe, following our efforts in the US.”

Kimchi is netting huge sales worldwide. Daesang dominates the export market – 60% of kimchi export sales are from Daesang. Their 2021 exports were $67 million, a 131% increase since 2016. European exports are increasing annually for the company at about 20%. The Netherlands and UK are the top European kimchi importers.

Read more (The Korea Herald)

- Published in Business